Late Additions

- Previously Running with IWS Lines

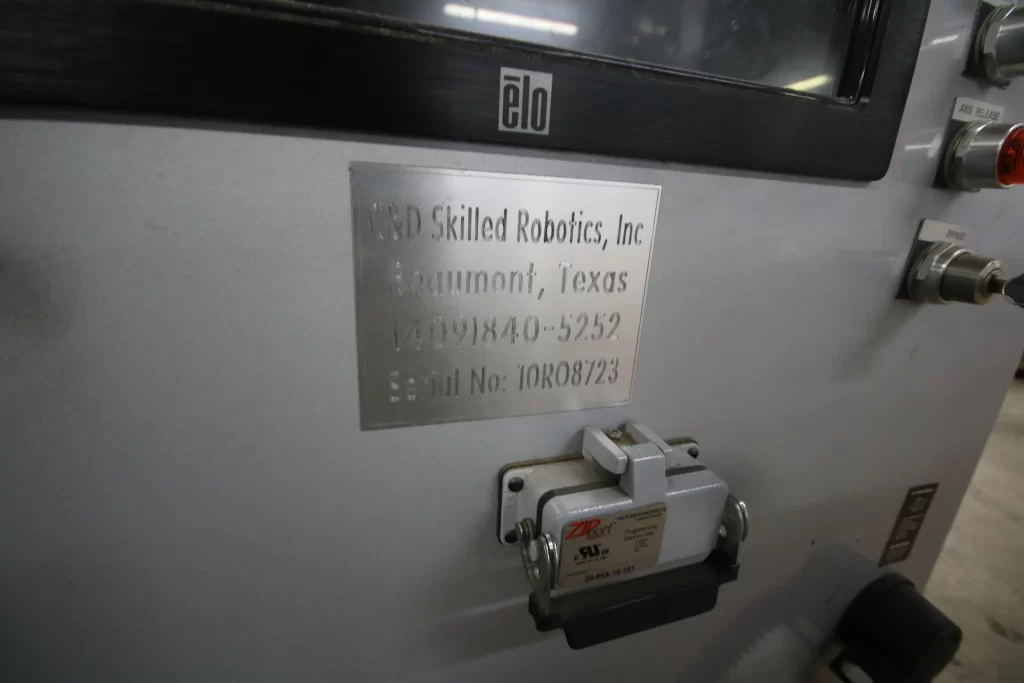

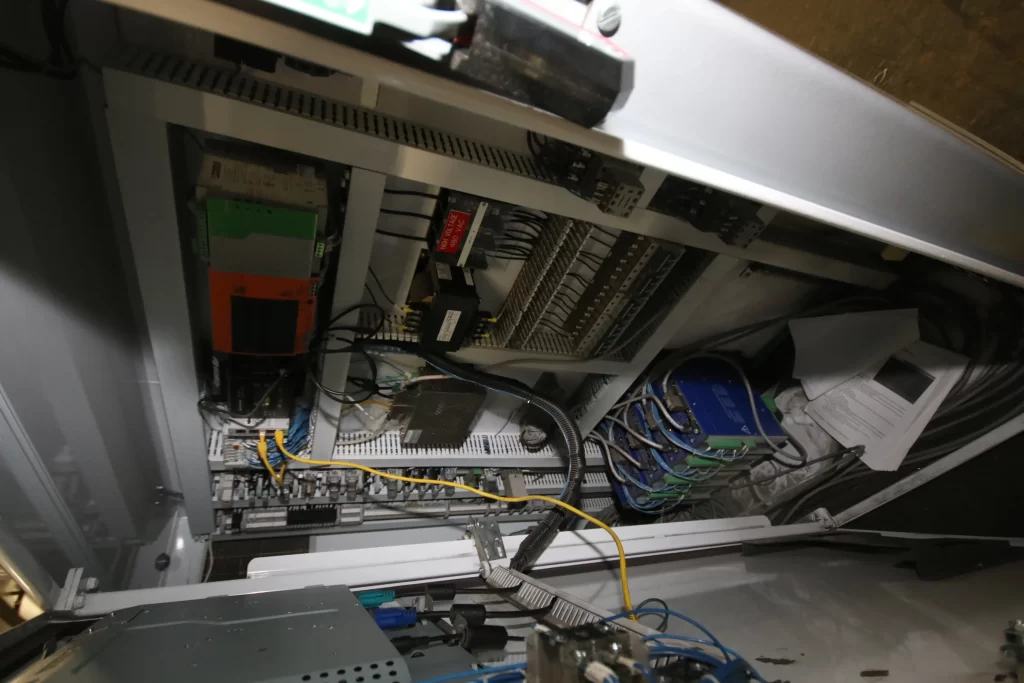

- 2011 C & D Skilled Robotics Palletizer, Model SKILLED504, S/N NR08723 with Prime Conveyor Inc. Pallet Stacker, Prime Infeed and Outfeed Roller Conveyor, PLC Controls, Servo Driven, Touchpad Display and Safety Cage

(2) SHREDDED CHEESE PACKAGING LINES

- SHREDDED CHEESE LINE (CURRENTLY SET TO RUN 8 oz., 12 oz., & 16 oz.)

- Includes:

- Marchant Schmidt 640 Block Cheese Cutter, S/N 14776-002 (NOTE: Shared with Line 34)

- Marchant Schmidt Aprox. 17 ft. L x 24″ W S/S Power Belt Conveyor, S/N 7140-03

- Marchant Schmidt Pneumatic Block Cuber, S/N 7140-0203 with Spare Knives

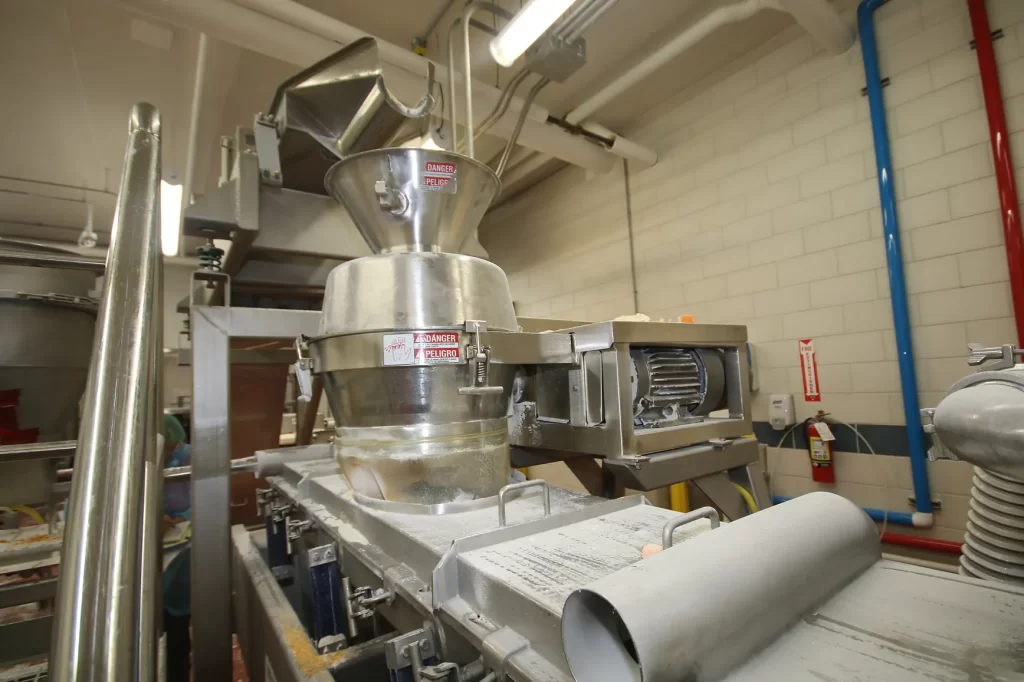

- (2) Marchant Schmidt S/S Ingredient Feeders

- Marchant Schmidt Aprox. 20 ft. L x 9 ft. 3″ H x 17″ W Incline Z-Configuration Belt Conveyor, S/N 7140-010 with Flights

- Key Aprox. 6 ft. L x 20″ W Vibratory Shaker Deck with S/S Stand

- Urschel 14″ S/ S Portable Shredder, Model CC-D, S/N 3533 with Spare Blades (#4281)

- Key Iso-Flex Aprox. 18″ W x 7 ft. L Enclosed S/S Vibratory Shaker, Mounted on S/S Stand

- 2-Door S/S Control Panel for Cutters and Shredders

- Marchant Schmidt 35 ft. L x 20″ W S/S Inclined Belt Conveyor with Ribbed Belt, S/S Stand and Drive

- VideoJet Ink Jet Coder, Model Excel 178i AF, S/N 990880007WD

- 2001 Ishida 24-Head S/S Rotary Bucket Scale, Model ADW-524SWCCW-M-224 D/30-WD-3A, S/N 42240 with 4-1/2″ W x 5-1/4″ L x 12″ Deep Scale Bucket, Ishida Digital Read-Out and Marchant Schmidt Aprox. 10 ft. H x 29 ft. W x 22 ft. W S/S Operators Platform, S/N 15124-002 with Diamond Plate Flooring, Handrails, Plastic Grating Stairs (NOTE: Platform Shared by Line 34 and Line 33)

- Key Aprox. 6 ft. L x 18″ W Vibratory Shaker Conveyor

- 2001 Butler Automatic Film Feeder/Splicer, Model SP1-351812, S/N J7241RH

- (2) Roll Lifter Carts

- 2001 Bossar Horizontal Form, Fill & Seal (Pouch Filler), Model B3700-D-XL, S/N 190033 with Allen Bradley PLC and PanelView 900 Touchpad Display

- 2-Door S/S Conveyor Control Panel

- Designer Systems Outfeed Product Conveyor with Intralox Belt

- Cintex S/S Metal Detector, S/N 01986, Mounted on Cintex S/S Conveyor, Model CS2084, S/N 38241

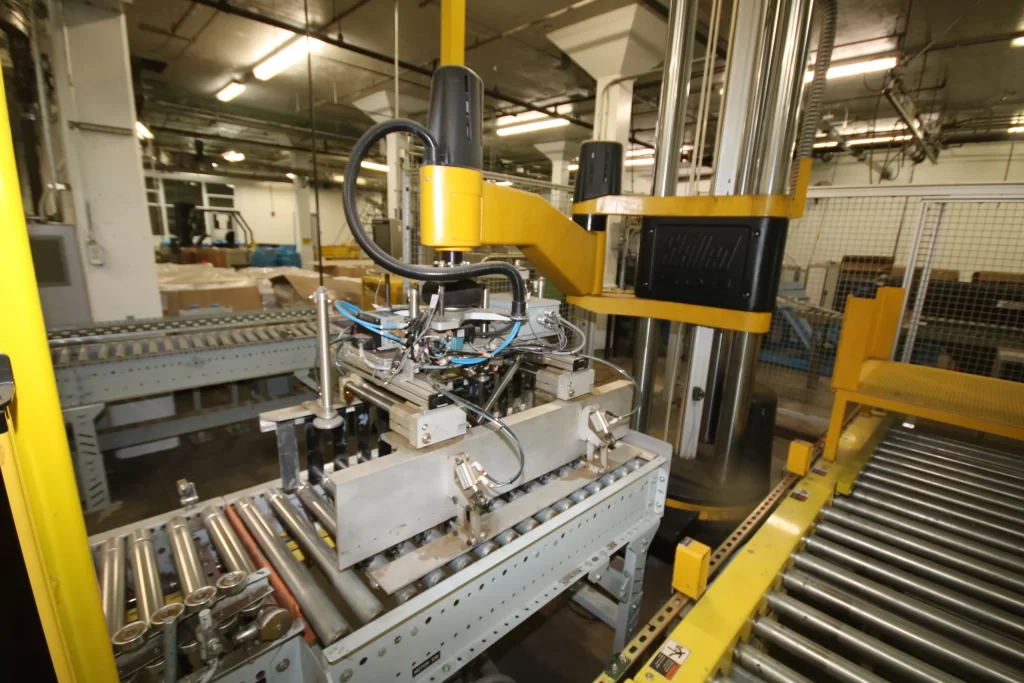

- Blue Print Automation Case Packer, Model 431, S/N – Job #11862-6 with Allen Bradley PLC Controls and Allen Bradley PanelView 600 Touchpad Display

- 2001 Nilfisk-Advance CFM Vacuum Dust Collector System, #01AB703

- Wexxar Boxformer/Erector, Model WFH, S/N 2260 with Nordson Gluer

- 2001 Wexxar Case Sealer, Model WSH66, S/N 2258 with Graco Invisi Pac HM25 Gluer

- Box Orienter

- Fox Jet Marksman Pro Box Coder, S/N MKP91801951 MKPRO with (2) Heads, Mounted on S/S Stand

- Mettler Toledo Checkweigher

- (Line #33)

SHREDDED CHEESE LINE (CURRENTLY SET TO RUN 8 oz., 12 oz. & 16 oz.)

- Includes:

- Marchant Schmidt 640 Block Cheese Cutter, S/N 14776-002 (NOTE: Shared with Line 33)

- Marchant Schmidt Aprox. 17 ft. L x 24″ W S/S Power Belt Conveyor, S/N 7140-001

- Marchant Schmidt S/S Pneumatic Block Lifter, S/N 7140-034

- Yale 1-Ton Pneumatic Hoist on Trolley with Jib Beam

- Marchant Schmidt Aprox. 15 ft. L x 16″ W Portable Infeed Belt Conveyor, S/N 13143-001

- Marchant Schmidt S/S Hydraulic Block Cuber, S/N 13143-002 with Spare Knives, Onboard Hydraulic Pump, Allen Bradley PLC Controls and PanelView 600 Touchpad Display

- Marchant Schmidt Aprox. 20 ft. L x 9 ft. 3″ H x 17″ W Incline Z-Configuration Belt Conveyor, S/N 13143-009 with Flights

- Marchant Schmidt S/S Ingredient Feeder, S/N 18740-001, Mounted on Portable Stand

- S/S Ingredient Feeder

- Urschel 14” S/S Portable Shredder, Model CC-D, S/N 3532 with Spare Blades

- Key Iso-Flo Aprox. 10 ft. 8″ L x 24″ W Enclosed Vibratory S/S Shaker Deck

- Marchant Schmidt Aprox. 4 ft. L x 24″ W S/S Tumbler, S/N 9163-001

- Marchant Schmidt Aprox. 35 ft. L x 20″ W S/S Inclined Belt Conveyor with Ribbed Belt, S/S Stand, Drive and Bottom S/S Pan

- 2005 VideoJet Ink Jet Coder, Model Excel 2000, S/N 053121047WD

- 2004 Yamato DataWeight 24-Head S/S Rotary Bucket Scale, Model ADW-524SW, S/N WG060351 with 4-1/2″ W x 5-1/4″ L x 12″ Deep Scale Bucket, Digital Read-Out and Marchant Schmidt Aprox. 10 ft. H x 29 ft. W x 22 ft. W S/S Operators Platform, S/N 15124-002 with Diamond Plate Flooring, Handrails, Plastic Grating Stairs (NOTE: Platform Shared by Line 34 and Line 33)

- Key Aprox. 5 ft. L x 23″ W Vibratory Shaker Conveyor

- 2009 Butler Automatic Film Stock Feeder/Splicer, Model SP1-3518-1.2, S/N J7319, 480 V, 3 Phase

- Bossar Horizontal Form, Fill and Seal (Pouch Filler), Model B-3700D, S/N 190044 with Allen Bradley PLC Controls and PanelView 1000 Touchpad Display (Dimensions Aprox. 22 ft. L x 7 ft. H x 7 ft. W) (Fills 8 oz. Pouches)

- Outfeed S/S Power Belt Conveyor AND Digital Scale, Model EK-600 Cintex S/S Metal Detector, S/N 98356, Mounted on Cintex Conveyor, S/N 38-2436

- Blue Print Automation Case Packer, Model 431, Order #11862-1-1 with Allen Bradley PLC Controls and Allen Bradley PanelView 600 Touchpad Display

- 2008 Wexxar Case Former, Model WF2H, S/N 3008 with Nordson ProBlue 7 Gluer

- Wexxar Box Sealer, Model WSH06, S/N 2259 with Nordson 3400V Gluer (Packs (12) 8 oz. Packages Per Box)

- Fox Jet Marksman Elite Box Coder, S/N FXJT 50901649 MK ELITE

- Box Orienter

- Mettler Toledo Checkweigher

- EZ Loader 2,500 lb. Capacity 42″ Scissorlift Platform with Ramp

- Spanco 130 lb. Pallet Positioner

- (Line #34)

RETAIL PACKAGING LINE

- RETAIL PACKAGING LINE (CURRENTLY SET TO RUN 8 oz., 16oz., & 2 lb.)

- Includes:

- Marchant Schmidt S/S Pneumatic S/S Block Lifter, S/N 7140-034, Set Up to Run 8 oz., 16 oz. and 2 lb.) and Ingersoll Rand Pneumatic Hoist with Trolley Mounted on Jib Beam

- 2000 Marchant Schmidt – Holly 640 S/S Fully Automatic Cheese Block Cutter, Model Holly Wright Pugson, S/N M9330H0L, Dimensions Aprox. 50 ft. L x 6 ft. 4″ W x 8 ft. 10″ H with Plexiglass Sides, Safety Guards, Allen Bradley PLC Controls, PanelView 1000 Touchpad Display, including Additional Cutting Head

- Marchant Schmidt Aprox. 10 ft. L x 24″ W S/S Power Belt Conveyor, S/N 726300

- Loma Systems IQ3 Metal Detector, S/N KCM0233251 with 9″ W x 3″ H Opening, Mounted on Cintex S/S Conveyor, Model CS2063, S/N 52505

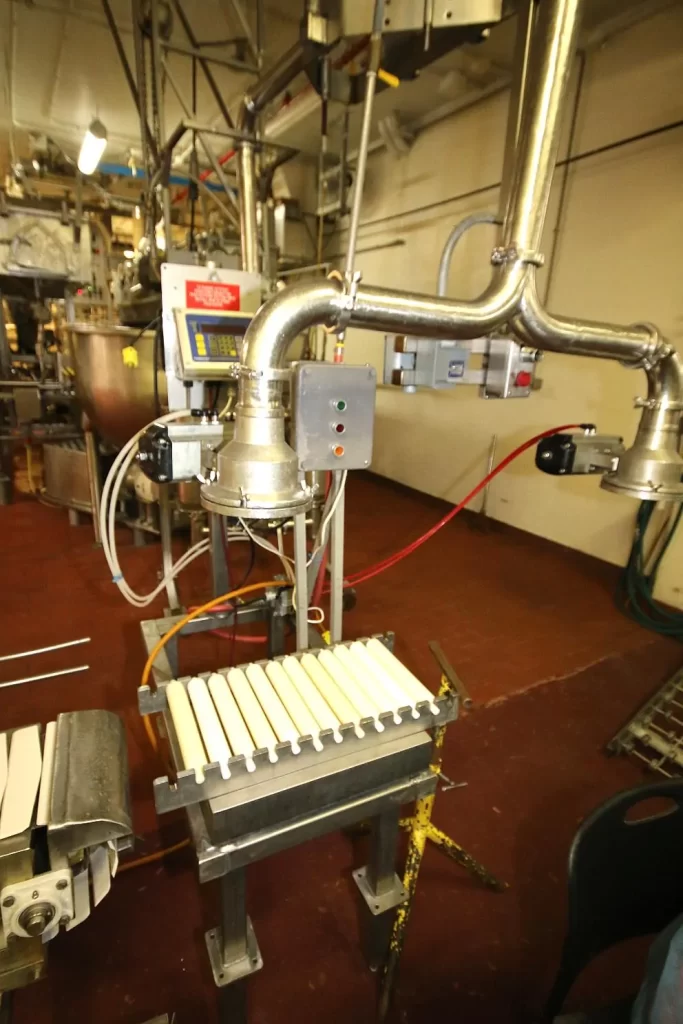

- 2007 Mettler Toledo Hi-Speed Checkweigher, S/N 0728521

- S/S Outfeed Product Conveyor with Marchant Schmidt Bridge Conveyor

- VideoJet Ink Jet Coder, Model Excel 2000, S/N 062221004WD

- 2001 Hayssen S/S Horizontal Wrapper, Model RT1800MAP, S/N R86692 with PLC Controls and Touchpad Display, 230 V, Single Phase

- Weightronix Digital Scale and S/S Tables

- ITW Minigrip Zip Pack Machine, Model D-22888RDH, S/N 01043001

- Label-Aire Roll Fed Labeler, Model 3111CD, S/N 0243380311, Mounted on Portable Stand

- Outfeed Belt and Roller Case Conveyor

- EZ Loader 42″ Scissorlift Platform

- Spanco 130 lb. Pallet Positioner

- Fox Jet Marksman Pro Ink Jet Coder with (2) Heads, Mounted on Stand

- (Line #35)

IWS LINE WEST (OPERATED AT APPROX. 800 SPM)

- Includes:

- Bosch/Kustner IWS Cheese Line Vertical Form, Fill and Seal, Model KE, S/N KE-211538 with Cooling Bath, Ultra Sonic Cutter, Stacker, 2011 Minomatic Wrapper, Type MS0430C, 3-Door Control with Siemens PLC Controls, Simatic Touchpad Display, 380 V, 3 Phase and Panel Infeed and Outfeed Conveyor

- VideoJet Ink Jet Coder, Model Excel 178i Auto Flush, S/N 991030017WD

- Campbells Sasib Horizontal Wrapper, Model WS-20II LH, S/N 4966-0012 with Infeed Stacker, PLC Controls, 460 V, 3 Phase Sasib Series II Touchpad Display with Infeed and Outfeed Conveyor, Set-Up to Wrap 16-Slices Per Pack (West)

- VideoJet Ink Jet Coder, Model Excel 170i, S/N I96E08006

- Mettler Toledo Hi-Speed Checkweigher, Job #070283E1

- Loma/Cintex Metal Detector, Model Sentry, S/N 11697 with 8″ W x 4″ H Product Opening, Mounted on S/S Conveyor

- Garvey Infeed and Outfeed S/S Product and Case Conveyor, Skate Conveyor and 2-Lane Magnetic Diverter Switch including Bridge Conveyor

- Douglas Case Packer with Case Loader and Nordson Gluer

- FoxJet Marksman Elite Case Coder with 2-Heads, Mounted on Stand

- Durable Packaging Top and Bottom Adjustable Case Sealer, Model RM-3, S/N 010783

- Fox Jet Marksman Elite Case Coder, Mounted on Stand

- Southworth Scissorlift Platform

- (2) EZ Off Lifter Aprox. 2,000 lb. Capacity with Ramp

- Spanco 130 lb. Capacity Pneumatic Pallet Positioner with Spreader

- (Line #45 – West)

IWS BRINE COOLING SYSTEM (KUSTNER)

- Kustner Cooling System includes: (2) Aprox. 300 Gal. (Aprox. 62″ H x 38″ W) S/S Tanks, WCB Centrifugal Pumps, Air Valves, Fittings, Related Piping and Flowverter Station

- 2-Door Control Panel for Kustner Cooling System with Honeywell Tru-Line Chart Recorder

- Chester Jensen S/S Plate Chiller, Size B8-0T-4-32, S/N 9732-P with (2) Fristam 7-1/2 hp Centrifugal Pumps

- Damrow 5,000 Gal. S/S Tank, S/N 144415 with Vertical Agitator, Painted Exterior, Valves, Tri-Clover 10 hp Positive Displacement Pump, Model PR125

- WCB 7-1/2 hp Portable Centrifugal Pump

(4) INDIVIDUAL WRAPPED SLICED CASTING LINES

- IWS CASTING LINE

- Marchant Schmidt 640 Block Cheese Cutter, S/N 14776-002 (NOTE: Shared with Line 34)

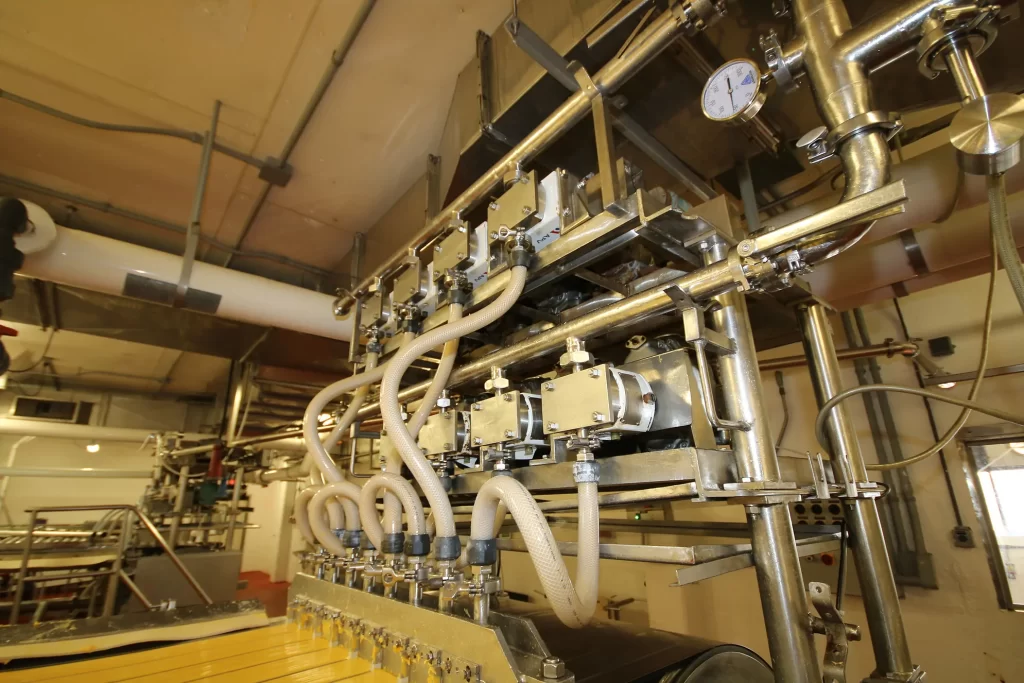

- Custom Design IWS Cheese Production Casting Line Table, Aprox. 38 ft. L x 36″ W at 8-Wide Sections, All S/S Constructed, Allen Bradley PLC Controls, PanelView 550 Touchpad Display, (8) APV Positive Displacement Pumps, Chilled Water Circulation with Drives, (6) Top Mounted Cooling Fan with Controls

- Eagle Belt Conveyor

- Outfeed Conveyor with Cheese Cutter

- (2) Custom Design IWS 4-Station All S/S Constructed Horizontal Wrappers with Stacker, Labeler and Controls

- L-Shaped Power Conveyor with Flights (Rework Conveyor)

- Mettler Toledo MicroMate Portable Checkweigher with Mounted Safeline Metal Detector with 8” W x 4” H Product Opening

- S/S Product Conveyor

- VideoJet Ink Jet Coder, Model Excel 178i Auto Flush, S/N 99082

- Durable Packaging Adjustable Top and Bottom Case Sealer, Model RA-4, S/N 0707B4

- Fox Jet Marksman Elite Case Coder, S/N 2003351 with Stand and Mounted on Titan Belt Conveyor

- EZ Off Lifter 2,500 lb. Capacity Scissorlift with Ramp

- (Line #11)

- Marchant Schmidt S/S Cheese Shredder, S/N 14776017

- (2) Urschel S/S Cheese Shredders, Model CC-D, S/N 4157 & S/N 4158 (Line #36)

- Other Additional Shredders To Be Added

- Custom Design IWS Cheese Production Casting Line Table, Aprox. 38 ft. L x 36″ W at 8-Wide Sections, All S/S Constructed, Allen Bradley PLC Controls, PanelView 550 Touchpad Display, (8) APV Positive Displacement Pumps, Chilled Water Circulation with Drives, (6) Top Mounted Cooling Fan with Controls

- Eagle Belt Conveyor

- Outfeed Conveyor with Cheese Cutter

- (2) Custom Design IWS 4-Station All S/S Constructed Horizontal Wrappers with Stacker, Labeler and Controls

- L-Shaped Power Conveyor with Flights (Rework Conveyor)

- Aprox. 16 ft. L x 8″ W Belt Rework Conveyor

- 1999 Campbells Sasib Horizontal Wrapper, Model WS-20II LH, S/N 5034-0049 with PLC Controls, Sasib Series II Touchpad Display with Infeed and Outfeed Conveyor, Set-Up to Wrap 16-Slices Per Pack

- VideoJet Ink Jet Coder, Model Excel Series 170i, S/N I94L01002

- 2010 Mettler Toledo Hi-Speed Checkweigher Scale, Model Belt Weigh XE, S/N 10005921

- Cintex Metal Detector, Model Sentry, S/N 11705 with 8″ W x 4″ H Product Opening, Mounted on S/S Conveyor

- Hi-Speed Magnetic Flow Director Lane Diverter

- Garvey Infeed and Outfeed Product Conveyor with Drives

- Conveyor Bridge

- Douglas Corrugated Case Packer, Model WACP-18, Project #M1556

- Fox Jet Marksman Elite Ink Jet Coder, Mounted on Belt Conveyor with Pack-off Table

- Durable Packaging Top and Bottom Adjustable Case Sealer, Model RM-3, S/N 065093

- Fox Jet Marksman Ink Jet Case Coder, Mounted on Stand

- EZ Off Lifter 2,500 lb. Capacity Scissorlift Platform with Ramp

- (Line #22)

IWS CASTING LINE – DELUXE LINE

- Line Includes:

- (2) Custom Design Aprox. 30 ft. L x 30” W S/S Casting Tables, Chill Water Cooled with Waukesha Positive Displacement Pump, (2) Top Mounted Fans, Allen Bradley PLC Controls and PanelView 600 Touchpad Display

- (2) G & H Positive Displacement Pumps and (1) APV Positive Displacement Pump, Top Mounted with S/S Hopper (Missing Head)

- Alfa Laval 7-1/2 hp Centrifugal Pump

- FMC Horizontal Wrapper

- Incline Conveyor with Flights

- Mettler Toledo MicroMate Portable Checkweigher with Mounted Safeline Metal Detector with 8” W x 4” H Product Opening

- S/S Product Conveyor

- VideoJet Ink Jet Coder, Model Excel 178i Auto Flush, S/N 99082

- Durable Packaging Adjustable Top and Bottom Case Sealer, Model RA-4, S/N 0707B4

- Fox Jet Marksman Elite Case Coder, S/N 2003351 with Stand and Mounted on Titan Belt Conveyor

- EZ Off Lifter 2,500 lb. Capacity Scissorlift with Ramp

- (Line #11)

3 LB. PACKAGING MACHINE

- Custom Design/Custom Packaging Machine 3 lb. IWS Portable Cheese Wrapper/Shear with Allen Bradley SLC 5/03 PLC, Servo Drive and PanelView 550 Touchpad Display

NH3 CHILLER

- Aprox. 21 ft. L x 28″ W Shell and Tube Chiller, NH3 Cooled with Aprox. 56″ W x 180″ W Accumulation System with Pump

- Skid-Mounted Plate Chiller with 2011 Alfa Laval Plate Press, Model M10-BWFD, S/N 30113-87435 with RVS Horizontal Receiver, S/N 45711 and Bell and Gossett Top Mounted Circulating Pump

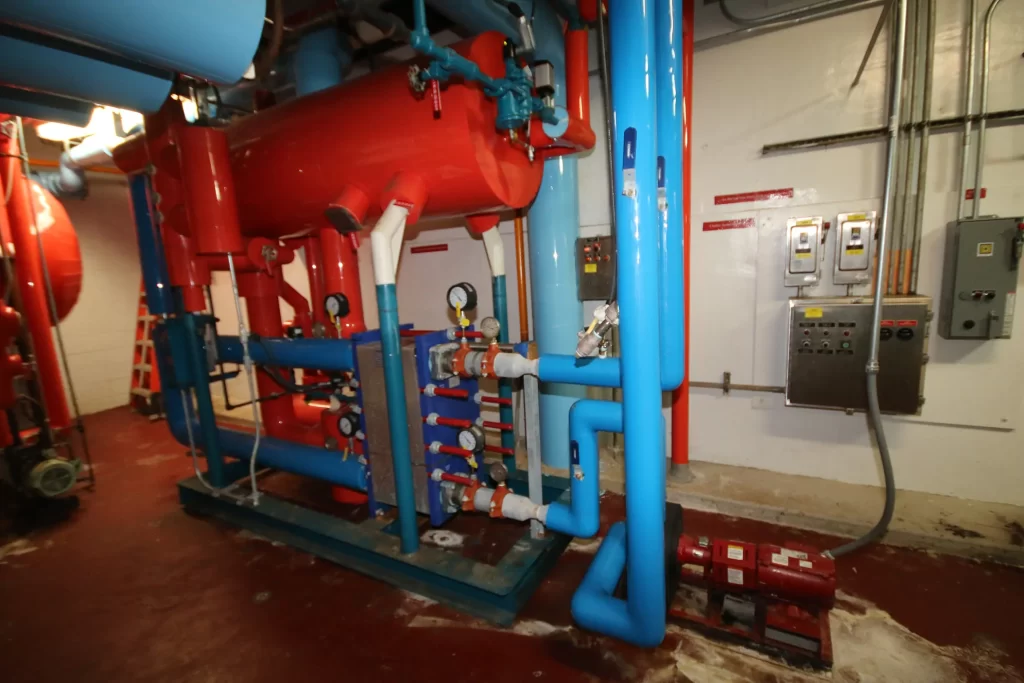

SWEET WATER COOLING SYSTEM

- Sweet Water Cooling System includes:

- (2) Aprox. 300 Gal. (Aprox. 59″ H x 39″ W) S/S Tanks with (3) Alfa Laval Centrifugal Pumps, G & H Air Valves, Filters and Related Piping (Line 45 Sweet Water Control)

- Sweet Water Cooling System with (2) Vilter Aprox. 9 ft. L x 12″ W Shell and Tube Chiller, S/N 26594-1 and S/N 26594-2

- (2) Lava Systems Inc. Chemical Feed Pumps and Emergency Eyewash/Shower System

ADDITIONAL CHEESE SHREDDERS

- Marchant Schmidt S/S Cheese Shredder, S/N 14776017

- (2) Urschel S/S Cheese Shredders, Model CC-D, S/N 4157 & S/N 4158 (Line #36)

CHEESE BAG IN BOX LINE (PROCESSED CHEESE)

- Bag In Box Packaging Line includes:

- Bulk 2-Head Bag In Box Filler with 10″ W Teflon Type Conveyor and Fairbanks Digital Scale

- Durable Packaging Adjustable Top and Bottom Case Sealer, Model RM-3, S/N 082952

- Fox Jet Marksman Elite Ink Jet Coder, Mounted on Conveyor

- Infeed and Outfeed Product and Skate Type Conveyor

- Interpack Bottom Case Sealer, Model USA20-SB-B0, S/N TM06211B009

- (40 lb. Line 04)

COMPLETE DIRECT STEAM INJECTION CONTINUOUS COOKER

- Late Model Skid Mounted System with 2010 Gold Peg Aprox. 40″ H x 40″ W Dome-Top Cone-Bottom S/S Mix Tank with Agitator, Bottom Mounted 2013 Waukesha Positive Displacement Pump, Model 134U2; SPX 20 hp Pump Shear; Alfa Laval Air Valve and Butterfly Valves; Mounted on Load Cells with Digital Read-Out including Operators Platform\

- 2010 Gold Peg International Rota Therm Steam Fusion Continuous Cooling Pasteurization System includes: Aprox. 90″ L x 48″ H x 36″ W S/S Ribbon Blender with Hinged Lid, Triple Drive Motor with Bottom Dual Auger Screw Conveyor, Cooker Motor Pump, Model C9810

- 2012 SPX/Waukesha Positive Displacement Pump, Model 134U2

- Skid-Mounted Unit with (2) Inoxba Dosing Pumps and SPX Centrifugal Pump

- Skid-Mounted Vacuum Pump System with Vac Pump, (2) Top Mounted Waukesha/SPX Positive Displacement Pumps, Model 060U2

- Aprox. 55″ H x 20″ W Cone-Bottom Plastic Flash Tank, Model 134U2 with Bottom Mounted Waukesha Positive Displacement Pump and SPX 190 hp Shear Pump, Related Valves, Piping and Controls

- SPX/Waukesha 30 hp Centrifugal Pump

- Cooker Supply Isolator S/S Control Panel (Located in Maintenance Shop)

- (NOTE: Operated with Former Natec IWS Line)

BARREL LIFT SYSTEMS

- (4) Barrel Lift Systems with Aprox. 21″ W x 20″ Deep x 40″ L Hydraulic Lifters with Hydraulic Pumps, Mounted on Aprox. 5 ft. L x 34″ S/S Roller Conveyors and Aprox. 7 ft. 8″ L x 42″ W Belt S/S Conveyors with Drive

CHEESE GRINDERS/EXTRUCTORS

- (2) 2013 & 2002 CFR S/S Cheese Grinders, Model CFR-24X, S/N 29197 and S/N 7375-0000 Grinder with 25″ Dia. Head, 75 hp, 1785 RPM, 230/460 V, 3 Phase, Inlet 37″ L x 30″ W x 42″ Deep with 36″ Extended Feed Hopper, Infeed and Outfeed Conveyor, Operators Platform and S/S Table

- (4) Rietz S/S Extructors/Grinders, Model RE-24-K9E943, S/N RE-750083, S/N RE-770438, S/N RE-732552 RE-84003084 with 24″ Dia. Heads, 30″ W x 36″L x 40″ Deep Hopper with 32″ Extended Hopper, Controls, 75 hp Motor, 1780 RPM460 V, 3 Phase and Operators Platform including Thru Floor S/S Hopper

- Marchant Schmidt S/S Cheese Shredder, S/N 14776017

- (2) Urschel S/S Cheese Shredders, Model CC-D, S/N 4157 & S/N 4158 (Line #36)

ADDITIONAL CHEESE CUTTERS & BLOCK TRANSFER CARTS

- 2006 Marchant Schmidt 640 lb. Pneumatic Block Cutter, S/N 7140002 with Controls and Other Size Cutters (Line #36)

- (3) Pneumatic S/S Cheese Cutters\

- (3) S/S Cheese Block Transfer Carts

- (3) Additional Marchant Schmidt Cheese Block Cutters in Line #33, #34 and #35 (Chunk Line)

ADDITIONAL S/S RIBBON BLENDERS

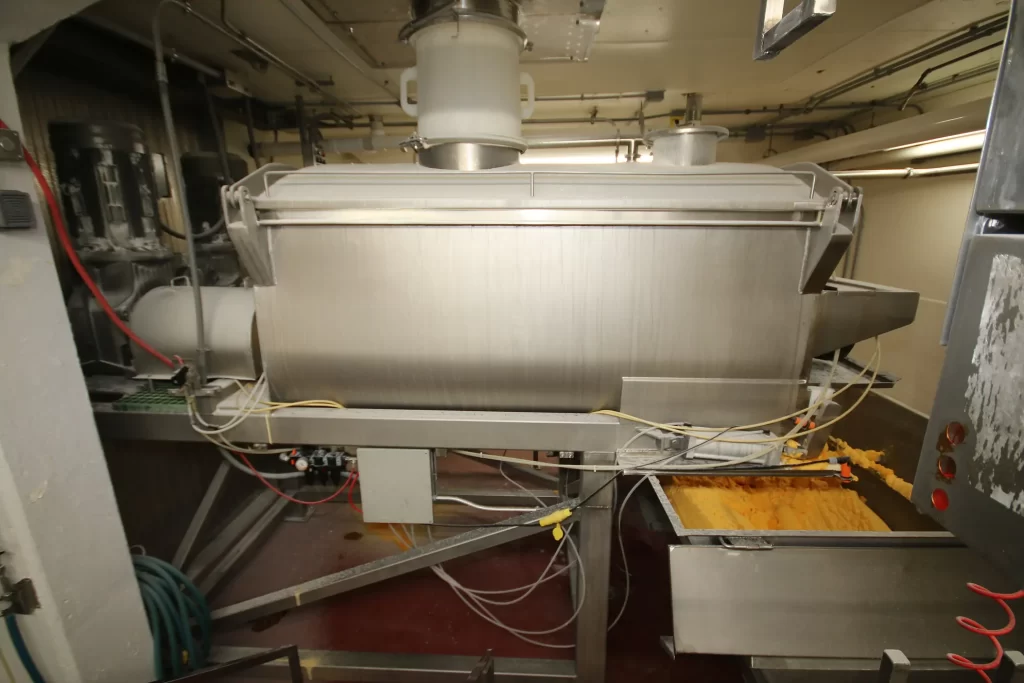

- (2) Mepaco 5,000 lb. Capacity S/S Ribbon Blenders, Model 170, S/N 14605 with Aprox. 10 ft. 4″ L Bottom Feed S/S Hopper Auger Conveyor, Pneumatic Hinged Lid, (2) 20 hp Bottom Feed Pumps, 7-1/2 hp Motor, 64″ W Conveyor and Allen Bradley PLC Controls

- Crepaco Aprox. 10,000 lb. Capacity Ribbon Blender with Aprox. 9 ft. x 6 ” Bottom Feed S/S Hopper Auger Conveyor, Pneumatic Hinged Lid, 10 hp and (2) 40 hp Motors, Allen Bradley PLC Controls and S/S Operators Platform

- 2010 CFR 5,775 lb. Capacity S/S Ribbon Blender, Sales #09-21727, S/N 21727-13028 with Pneumatic Hinged Lid, (2) 40 hp Motors, 240/460 V, 3 Phase

- (4) Blenders in Line #45 System 7; Line #11 System 4; Line #16 and 40 lb. Line

S/S KETTLES

- Aprox. 300 Gal. (Aprox. 46″ H x 50″ W) S/S Kettle with Baffle, Scrape Surface Agitator (Note: No Jacket)

- (2) Additional Kettles on Line #16 and 40 lb. Line

ADDITIONAL LIKWIFIERS

- Breddo 300 Gal. Insulated S/S Likwifier, Model LDT, S/N D21522-298369 with WCB 20 hp Pump, Allen Bradley PLC Controls, PanelView 550 Touchpad Display, Aprox. 37.5 hp Motor, Mounted on Load Cells with Emery Digital Scale with Read-Out including S/S Operators Platform

- (3) Breddo 250 Gal. S/S Insulated Likwifiers, Model LDT and Model LDD, S/N D34872-298549, S/N 98041-D3306-5 and S/N N/A with WCB Air Valves, Tri-Clover Pumps, Mounted on Load Cells and Operators Platforms

- Aprox. 250 Gal. S/S Likwifier

- (3) Additional Likwifiers Line #10, Line #16 and Line #45- System 7

(4) CIP SYSTEMS

- 4-Tank Skid-Mounted S/S CIP System including (1) Aprox. 36″ H x 36″ W S/S Tank, (3) Aprox. 48″ H x 40″ W S/S Tanks, APC Air Valve, APV Pump, Allen Bradley PLC Controls and PanelView 550 Touchpad Display

- 4-Tank Skid-Mounted S/S CIP System with (2) Aprox. 62″ H x 44″ W S/S Tanks and (2) Aprox. 74″ H x 44″ W S/S Tanks; Alfa Laval Air Valves, (2) Tri-Clover Pumps, Related Piping and Operators Platform

- 3-Tank CIP System with (2) Aprox. 200 Gal. (Aprox. 48″ H x 36″ Dia.) S/S Tanks and (1) Aprox. 300 Gal. (Aprox. 59″ H x 40″ W) S/S Tank with ABB Aprox. 10 hp Centrifugal Pump, Alfa Laval Air Valves, Controls and Chemical Handling System3-Tank CIP System with (2) Aprox. 200 Gal. (Aprox. 48″ H x 36″ Dia.) S/S Tanks and (1) Aprox. 300 Gal. (Aprox. 59″ H x 40″ W) S/S Tank with ABB Aprox. 10 hp Centrifugal Pump, Alfa Laval Air Valves, Controls and Chemical Handling System

- Skid-Mounted Late Model 3-Tank CIP System with (1) Sani-Matic Aprox. 480 Gal. (Aprox. 67″ H x 41″ W x 41″ W) S/S Tank and (2) Aprox. 320 Gal. (Aprox. 45″ H x 41″ W x 41″ W) S/S Tanks with Steam Injected, Flow Meter, Fristam 25 hp Centrifugal Pump, WCB Air Valves, Pneumatic Ball Valves, Inline Filter, Related Piping, Allen Bradley Controls, PanelView 550 Touchpad Display, Honeywell Chart Recorder (Note: No Shell and Tube)

- Aprox. 300 Gal. (Aprox. 60″ H x 38″ W) Hinged Lid Vertical S/S Tank (Sodium Citrate Rinse Tank)

ADDITIONAL CASE FORMER

- 2006 Wexxar Case Former, Model WF-2H, SN 3064 with Nordson ProBlue 7 Gluer (Line #36)

- (3) Additional Case Formers on Line #33, Line #34 and Line #35 (Chunk Line)

ADDITIONAL CHECKWEIGHERS

- Mettler Toledo S/S High Speed Checkweigher, Model Belt Weigh XE, S/N 10005922

- Mettler Toledo MicroMate Hi-Speed Checkweigher (Line #36)

- (11) Additional Checkweighers on Line #35 (Chunk Line), Line #33, Line #34, Line #16 – North and South, Line #45 – East and West; Line #11 (Deluxe IWS); Line #22, Line #23, Line #24

ADDITIONAL METAL DETECTORS

- (3) Cintex Metal Detectors with 8″ W x 4″ H Product Opening, Mounted on S/S Conveyors

- Cintex S/S Metal Detector with 9″ W x 8″ H Product Opening, Mounted on Portable S/S Frame (Located Cooler 1-3)

- Cintex Metal Detector, S/N KMC17136 with 12″ W x 4″ H Product Opening, Mounted on Conveyor (Line #36)

- (9) Additional Metal Detectors on Line #35 (Chunk), Line #34, Line #33, Line #16 – North, Line #45 – East and West, Line #22, Line #23, Line #24

LABELERS

- (3) Avery Pressure Sensitive Labelers, Model 500LH, S/N 405358, S/N 405362 and S/N 405356, Mounted on Stand, 115 V, Single Phase (1-Located Cooler 1-5)

- (2) Label-Aire Pressure Sensitive Labelers, Model 3111CD, S/N 02494704405 and S/N 0240980309L, Mounted on Portable Stands

- (3) Additional Label-Aire Portable Pressure Sensitive Labelers, Mounted on Stands (Located Label Room) and (1) on Line #35

ADDITIONAL PACKAGING MACHINES

- 2010 Barry Wehmiller Rose Forgrove Flowpack Horizontal Packaging Machine, Model RF305HSE, S/N 50993, Currently Set-Up to Run 16-Slice Twin Pack, PLC Controls with Touchpad Display, 480 V, 3 Phase

STEAM GENERATOR/BOILER

- 2008 Clayton 600 hp Vertical Steam Generator/Boiler, Model SE00-604-1, S/N 24568, Input Heat Max 24,199,000, 480 V, 3 Phase

AIR COMPRESSOR

- 2012 Gardner Denver 300 hp Air Cooled Air Compressor, Series VS, 115 psi, 19,367 Hrs.

- 2003 Sullair 300 hp Air Cooled Rotary Screw Air Compressor, Model LS255 300H/A/SUL, S/N 003-130473

REFRIGERATED AIR DRYER

- Late Model Gardner Refrigerated Air Dryer, Model RSD1500A4, S/N 1000002835797 with Refrigerant R404A, 460 V, 3 Phase

VACUUM PUMPS

- (2) Sullair 15 hp Vacuum Screw Pumps, Model RSVS10-15A-AC, S/N 003-V82066 (#3) and S/N 003-V82773, 195 scfm, 3600 Rated RPM

MAINTENANCE SHOP

- (2) Portable Burning Carts with Torches and Regulators; Miller Miller-Matic 130XP Welder; Miller Shop Master 300 AC/DC Mig Welder with Mig and Stock; Miller Max Star 150STH Mig Welder; Miller Dialarc 250 AC/DC Stick Welder; Miller Spectrum 500 DC Plasma Cutter; Welding Curtain; Welding Table with Vise; Dayton 9×16″ Horizontal Band Saw; Grob Inc. Vertical Band Saw; Wilton Disc and Belt Sander; (4) Dayton and Other Double End Grinders; Lincoln Electric Portable Fume System; Pipe Stands; New Heaters; Blowers; Die Lifting Carts; Steel Portable Dump Hopper; Ridgid Pipe Threader; Rivers Engraver; (3) Flammable Cabinets; Cordless Hand Tools by Milwaukee and Others; Anvil; Hydraulic Jacks; Hydraulic Press; Johnson Bar; Chains; Ridgid Pipe Equipment; (2) Safety Kleen Parts Washers; Safety Harnesses; (30) Steel Workbenches – Some with Vises; (2) Dake Arbor Presses; Portable Boom Crane; Ager Dynamig 1760G Horizontal Lathe with 6 ft. Bed, 3-Jaw Chuck, Tailstock, Hold-Downs and Newall Controller; Southbend Horizontal Lathe with 5 ft. Bed and 3-Jaw Chuck (Vintage); Dayton 20″ Pedestal Drill Press, Model 6W282A with Machinist Vise; Bridgeport Vertical Mill Machine, Model 129120 with Machinist Vise; Bridgeport Rotary Table; Milwaukee Pedestal Drill Press (Vintage) Nut and Bolt Hardware, S/S and Steel; Blueprint Cabinets; Dayton Shop Vac; Brute Steel Surface Plate; Portable Welder, Mounted on Electric Pallet Jack; Workbenches; Vises; Safety Kleen Parts Washer; CM 2-Ton Electric Hoist; Grasso Portable Reciprocating Air Compressor; Milwaukee Core Drill, Dymo Drill Cat #4096 with Accessories; Shop Vacs; Workbenches; (2) Ridgid Sewer Cleaners – (1) High Pressure Pump Type; Ridgid 1822-1 Pipe Threader with Dies; Enerpac Cyclone Portable Condulet Bender; Knaak Portable Gang Box; Cabinets; Delta Vertical Drill Press; Movin Cool Portable Air Conditioners; Oil Evacuation Pump System; Miscellaneous Hand Tools

GENERAL PLANT

- Ideal Wire Stitcher, Model S-1244, S/N A-30156; Aprox. 5 ft. 8” L x 49” W x 48” Deep 4-Wheel Portable S/S Cage Carts; Aprox. 56” L x 30” W x 20” Deep 4-Wheel S/S Tubs; (40) Rubbermaid Dumpsters; Rubbermaid 4-Wheel Carts; Rubbermaid Cabinets; Wall Mounted Cabinets; S/S Stands; S/S Tables; Trash Cans; Foaming Stations; Emergency Eyewash Stations; Warehouse Mirrors; Kronos Time Clock, Aero S/S Sink with Sprayer; S/S Sinks; S/S Tables; 4-Wheel S/S Cart; Foreman’s S/S Desks; Barrel Dollies; Flammable Storage Cabinet; Cage Racks; Large Circulating Fans; Portable Stairs; Bridge Conveyors; Portable Foamers; Dollies; S/S Wash Baskets & Tubs; Portable Hose Rack with High Pressure Hoses & Wands; (2) Beverage Aire and Manitowoc 3-Door Glass Coolers; Beverage Aire Single Door Glass Cooler; Merchandising Counter with Cash Register; Quality Control Heat Seal Vacuum Leak Detection System; Ladders

HIGH PRESSURE PUMPS

- Hot Water High Pressure Pump System with (2) Rotary Jet 75 hp High Pressure Pumps, Model RGB

- High Shear Pumps include: Admix 7-1/2 hp High Shear Pumps

- Positive Displacement Pumps include: APV & SPX Positive Pumps

- Centrifugal Pumps include: Alfa Laval, APV, SPX, Tri-Clover, G & H and Other Centrifugal Pumps – Up to 15 hp

- Inline Filters include: Tri-Clover 3” Inline Single and Main Stream Dual Filter Systems on Racks and S/S Mag Traps

- VFD’s include: Allen Bradley PowerFlex, Reliance SP4500 and Safety Switches

- S/S Piping, Valves, Fittings, Flowverter Stations Throughout Facility

COP/WASH TROUGHS

- Aprox. 12 ft. L x 35” W x 34” H Jet Spray S/S COP/Wash Trough with (2) Ampco Centrifugal Pumps, Controls and Walk Platform

- Aprox. 74” L x 33” W x 35” Deep Jet Spray S/S Wash Trough with Centrifugal Pump and Operators Platform

- Aprox. 33” W x 75” L x 35” Deep Jet Spray S/S COP Tank with Tri-Clover Centrifugal Pump

- (4) S/S Wash Trough/COP Tanks with Centrifugal Pumps (Located on 2nd Floor)