5,000 LBs/Hr. HTST Pasteurize System

- WCB S/S Plate Press, M/N T13CH-AL-1, S/N 5057, Test PSI 200, Design PSI 150, Built by UDMC, (2) Dividers, 145 Plates, Includes Flow Diversion Valve, 2” Holding Tube, 16” Tall x 27.5” Dia. S/S Balance Tank, Hinge Lid

- APV 25 hp Homogenizer, Type 24-3B, S/N 1-01,624, Max. Pressure 210

- Hot Water Set Mounted on S/S Skid, Nat’l Bd. 88536, Part No. BY526006024001, S/N 789526-01, 29” L x 8 ½” Dia. with SPX WCB 7.5 hp S/S Centrifugal Pump, Aprox. 1 ½” x 1 ½” S/S Clamp Type Head, 3520 RPM, 208-230/460 Volts

- WCB 10 hp Centrifugal Pump, M/N 2085LV, S/N 384115-05, with Aprox. 1” x 2” Clamp Type S/S Head, with Baldor 3450 RPM Motor, 208-230/460 Volts

- WCB 1.5 hp Centrifugal Pump, M/N 2065LV, S/N 384116-05, with Aprox. 1” x 1” Clamp Type S/S Head, with Baldor 1755 RPM Motor, 208-230/460 Volts

Cooking Kettles

- Lee 300 Gal. S/S Kettle, M/N 250U9MS, S/N 19108-1-1, MAWP Jacket 100 PSI @ 338 F, MDMT Jacket -20 F @ 100 PSI, NAT’L BD 8643, Cone Bottom, with Sweep/Scrape Agitation, with 5 hp SEW Agitation Motor, Hinge Lid, S/S Legs, Internal Dims.: 17” Deep x 72” Dia., Overall Dims.: 71” Tall x 76” Wide

- Lee 300 Gal. S/S Kettle, Lee S/S Kettle, M/N 250U9MS, S/N 19108-1-3, MAWP Jacket 100 PSI @ 338 F, MDMT Jacket -20 F @ 100 PSI, NAT’L BD 8645, Cone Bottom, with Sweep/Scrape Agitation, with 5 hp SEW Agitation Motor, Hinge Lid, S/S Legs, Internal Dims.: 17” Deep x 72” Dia., Overall Dims.: 71” Tall x 76” Wide

- Lee 300 Gal. S/S Kettle, M/N 250U9MS, S/N 19108-1-2, MAWP Jacket 100 PSI @ 338 F, MDMT Jacket -20 F @ 100 PSI, NAT’L BD 8644, Cone Bottom, with Sweep/Scrape Agitation, with 5 hp SEW Agitation Motor, Hinge Lid, S/S Legs, Internal Dims.: 17” Deep x 72” Dia., Overall Dims.: 71” Tall x 76” Wide

- Lee 140 Gal. S/S Kettle, M/N 100D7T, S/N 1699A2, Jacket 90 PSI @ 332 F, Test Pressure 140 PSI, NAT’L BD 3692, with Sweep/Scrape Agitation, SEW 1 hp Agitation Motor, Hinge Lid, S/S Legs, Internal Dims.: 31” Deep x 36” Dia., Overall Dims.: 72” Tall x 58” Wide

- Lee S/S Kettle, M/N 100D9MT. S/N A7863-2, Jacket 90 PSI @ 332 F, Test Pressure 155 PSI, NAT’L BD 2962, with Sweep/Scrape Agitation, SEW 1 hp Agitation Motor, Pressure Sealed Lid, S/S Legs, Overall Dims.: 78” Tall x 62” W

- Lee S/S Kettle, M/N 100D9MT. S/N A7863-1, Jacket 90 PSI @ 332 F, Test Pressure 155 PSI, NAT’L BD 2961, with Sweep/Scrape Agitation, SEW 1 hp Agitation Motor, Pressure Sealed Lid, S/S Legs, Overall Dims.: 78” Tall x 62” W

Processing & Mixing Tanks

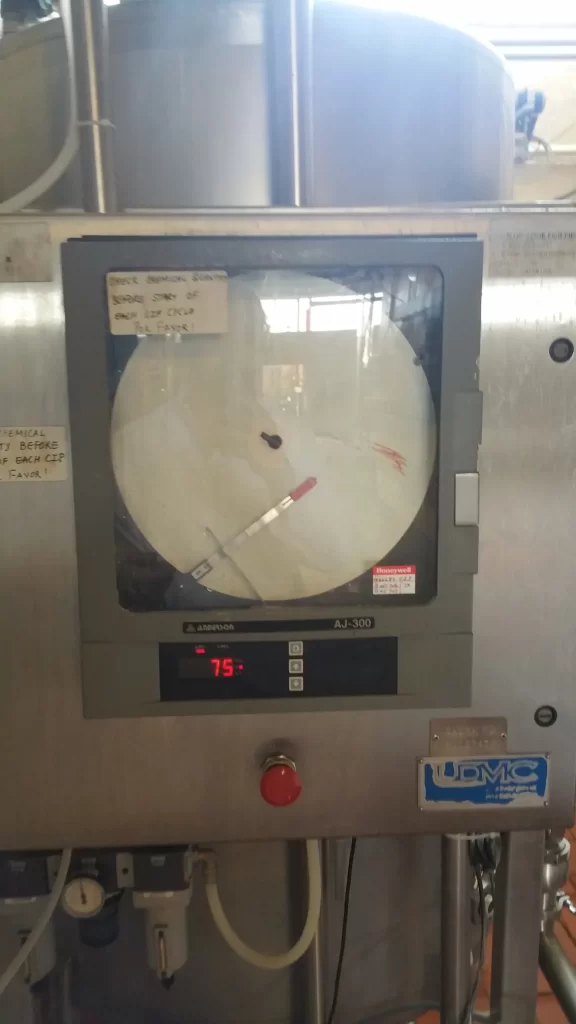

- Mueller 1,000 Gal. S/S Fermentation/Processing Tank, Cone Bottom, Sweep/Scrape Agitation, Dual CIP Spray Balls, SEW 11/23 hp Agitator Motor, S/S Legs, with Anderson AJ-300 Chart Recorders. Internal Dims.: 47” Deep x 80” Dia., Overall Dims.: 126” Tall x 86” Wide

- Mueller 1,000 Gal. S/S Fermentation/Processing Tank, Cone Bottom, Sweep/Scrape Agitation, Dual CIP Spray Balls, SEW 11/23 hp Agitator Motor, S/S Legs, with Anderson AJ-300 Chart Recorder. Internal Dims.: 47” Deep x 80” Dia., Overall Dims.: 126” Tall x 86” Wide

- Regis 450 Gal. S/S Fermentation/Processing Tank, S/N 9932 Heat Exchange Jacket 50 PSIG, CIP Spray Ball, NORD Agitation Motor, S/S Legs, with Anderson AJ-300 Chart Recorder, Internal Dims.: 29” Deep x 69” Dia., Overall Dims.: 118” Tall x 72” Wide

- MIXING TANKS

- Walker 600 Gal. Mix Tank, S/N 298, Mounted on S/S Skid, with Anderson AJ-300 Chart Recorder, Overall Dims. 91” Tall x 71” Dia.

- Walker 600 Gal. Jacketed Mix Tank, Mounted on S/S Legs, with Anderson AJ-300 Chart Recorder, Overall Dims. 91” Tall x 71” Dia.

- Walker 600 Gal. Mix Tank, Mounted on S/S Skid, with Anderson AJ-300 Chart Recorder, Overall Dims. 91” Tall x 71” Dia.

Breddo Likwifiers

- Breddo 50 Gal. Likwifier, S/N 263445 2 01037, with Breddo 15 hp Motor, 1765 RPM, 203-230/460 Volts, Internal Dims.: 24” L x 24” W x 23” H, Overall Dims.: 57” Tall x 26” Wide

- Breddo 50 Gal. Likiwifier, M/N LDT, S/N D32545-2 88173, with Breddo 10 hp Motor, with Allen-Bradley Starter, Internal Dims.: 24” L x 24” W x 23” H, Overall Dims.: 57” Tall x 26” Wide

Horizontal S/S Holding Tanks

- 4,000 Gal. S/S Horizontal Tank, with CIP Dual Spray Ball, Top Mounted Single Prop Agitation, with Thermometer and Air Valve, Internal Dims.: 12’ 4” (148”) Long x 7’ 10” (94”) Dia.

- 4,000 Gal. S/S Horizontal Tank, with CIP Dual Spray Ball, Top Mounted Single Prop Agitation, with Thermometer and Air Valve, Internal Dims.: 12’ 4” (148”) Long x 7’ 10” (94”) Dia.

Cup Filling Lines

- Pack Line 2-Wide Cup Filling Line, Model PXM-4, S/N PL 710045, Currently Set Up to Run Approx 4-1/2″ Dia 10 Oz Cups @ 60 Cups Per Minute, Believed Capable of 70 Cups Per Minute, Previously Filled 10 & 24 Oz Cups, 3-Door S/S Electrical Control Panel Equipped with Allen Bradley 13-Slot SLC 5/03 CPU PLC Controller,Operator Touch Screen Controls, Portable COP Cart Equipped with 7-1/2 HP WCB Centrifugal Pump (3450 RPM) for Parts Cleaning & (2) Operator Platforms

- Pack Line 2-Wide Cup Filling Line, Model PXG-2, S/N PL 700289, Currently Set Up to Run Approx 4-1/2″ Dia 10 Oz Cups @ 50 Cups Per Minute, Believed Capable of 70 Cups Per Minute, Previously Filled 10, 14 & 28 Oz Cup

Additional Equipment on Processing Room Floor

- Quadro Ytron 7.5 hp All S/S Shear Pump, S/N Z100 2004, Mounted on S/S Portable Cart

- (5+) SPX Positive Displacement Pumps

- (8+) Tri-Clover Centrifugal Pumps

- Air Valve Manifolds

- (2) 80″ X 27″ COP Tanks with Centrifugal Pump

- SPX Tri Blender (Like New)

- SPX Positive Pump 045/U2 (Like New)

CIP, COP and Chemical Dosing Systems

- United Dairy Machinery Corporation (UDMC) 3-Tank Skid Mounted Approx 300 Gallon CIP System, All S/S Shell and Tube Heat Exchanger, WCB 20-HP Centrifugal Pump, 3525 RPM, Anderson AJ-300 Onboard Chart Recorder, Associated Valves, Meters, Filters, & Fittings (Approx Tank Dimensions: 38″ D x 65″ H)

- Jet Spray S/S COP Tank. Approx 78″ L x 24″ W 17″ D, Tri-Clover Centrifugal Pump, Anderson AJ-300 Chart Recorder. Anderson Temp Probe

- Chemical / Sterilizer Dosing System, Diversey Conductivity Control Unit, DWC-1000 Concentration Computer, Diversey P-6100T, DWC-1000 Cencentration Computer, DiverseyP-6100T.

Stein Continuous Fryer

Stein Conveyorized Fryer, Model FB-20, S/N 445 Flow Through Conveyorized Oil Fryer with Oil Reclaim System

Urschel Shlicer

Urschel All S/S Slicer, Model G, S/N 695, 2-Cutting Wheels System, 2 HP, 1735 RPM, Portable Unit Mounted on Casters, Previously Used to Slice Vegetables (Onion, Carrot, Garlic, Eggplant & More)

2016 10-Ton Aaon Air Handler

- 2016 AAON 10-Ton Air Handler, Model RN-010-8-0-EB09-121, S/N 201604-ANEJ13939, 3500 RPM, Design Pressure Low Side 255, Design Prssure High Side 475, 208V, 3 Ph

Air Compressors

- 2015 Hydrovane Air Compressor, Model HVFR 2B, S/N D145748, Max Pressure 115, 1775 RPM, 200/3/60, WEG 22 kW Motor, 200-230/400- (Installed New 2016)

- 2015 Beko Drypoint RA Air Dryer, S/N 150015141/15,150 SCFM,203 PSI, 2.3 L

- Quincy 30 HP Air Compressor, Model 0MT30ACA12SF, 87470

Boiler Room

- Fulton Vertical Natural Gas Boiler. Model FB-030-A, S/N 99535, 150 MWP, 1035 MD Lbs Steam/Hr, 5/16 SH, 5/8 HD, 90 HS, Gas Supply Pressure 7 IN WC Min & 13 IN Max, 120V/60Hz/1, National Board No 99535

- Industrial Boiler Company Natural Gas Boiler, Model MIIPFDHI 60 G02, S/N S 6062, 150 MWP, 300 SQ Ft Heating Surface, 5/16″ Shell Thickness

- Lockwood Products Condensate Accumulation Tank, (2) Condensate Pumps

- Shell and Tube Heat Exchanger, Approx 72″ Long

- Shell and Tube Heat Exchanger, Approx 62″ Long

- (2) Vertical Receivers

Laboratory and Analytical Equipment

- TA XT Plus Texture Analyzer

- Ohaus MB45

- Sartorius MA100

- Polystat Water Bath

- (5) Lab fridges