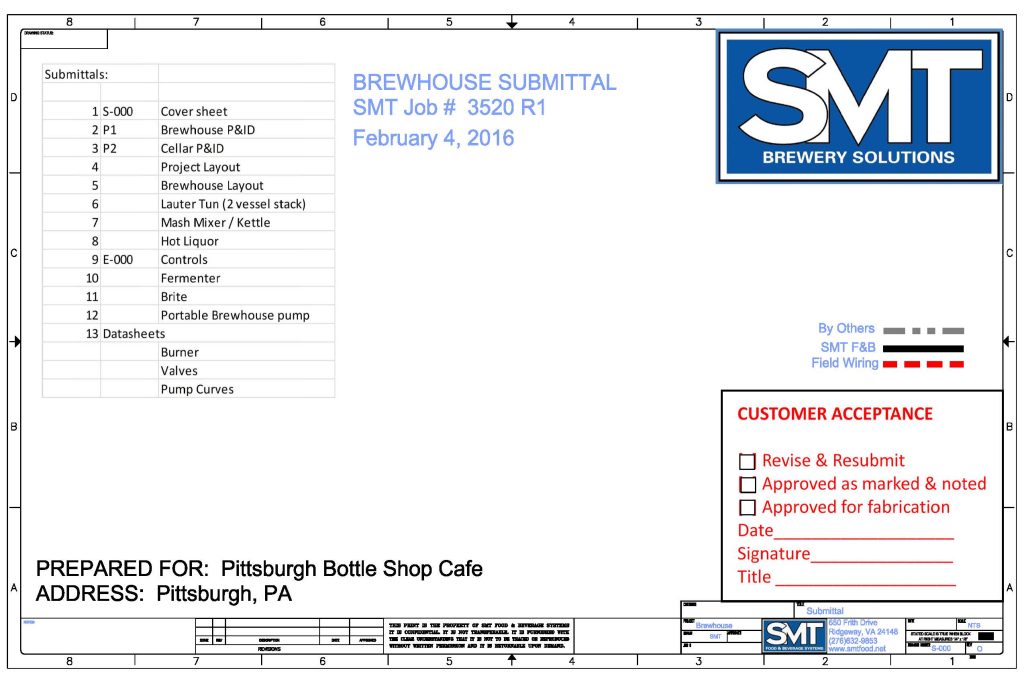

BREWHOUSE SYSTEM

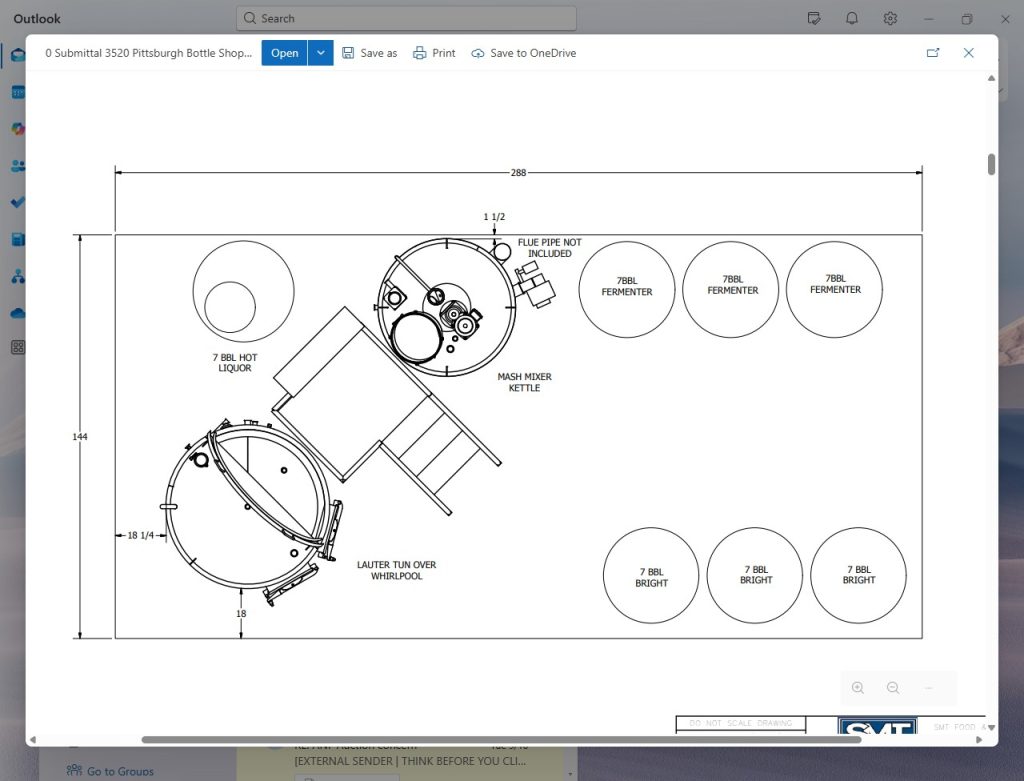

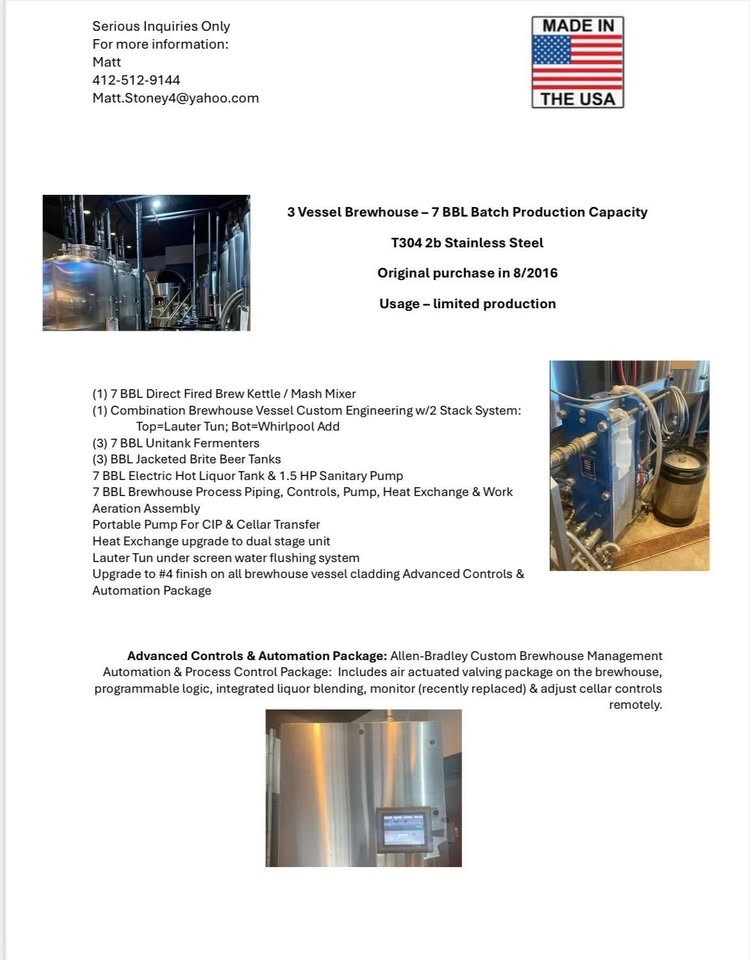

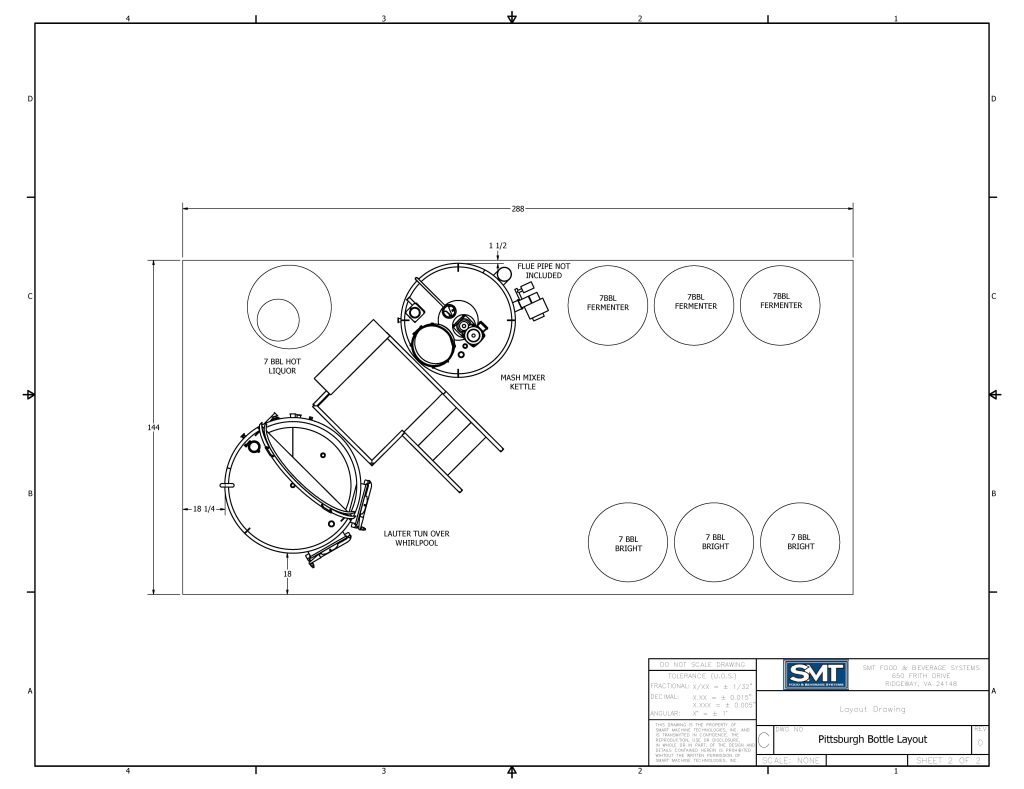

- 2016 PRISTINE (3) VESSEL BREWHOUSE SYSTEM – 7 BBL BATCH PRODUCTION CAPACITY ( Additional images below the information )

BREWHOUSE SYSTEM INCLUDES:

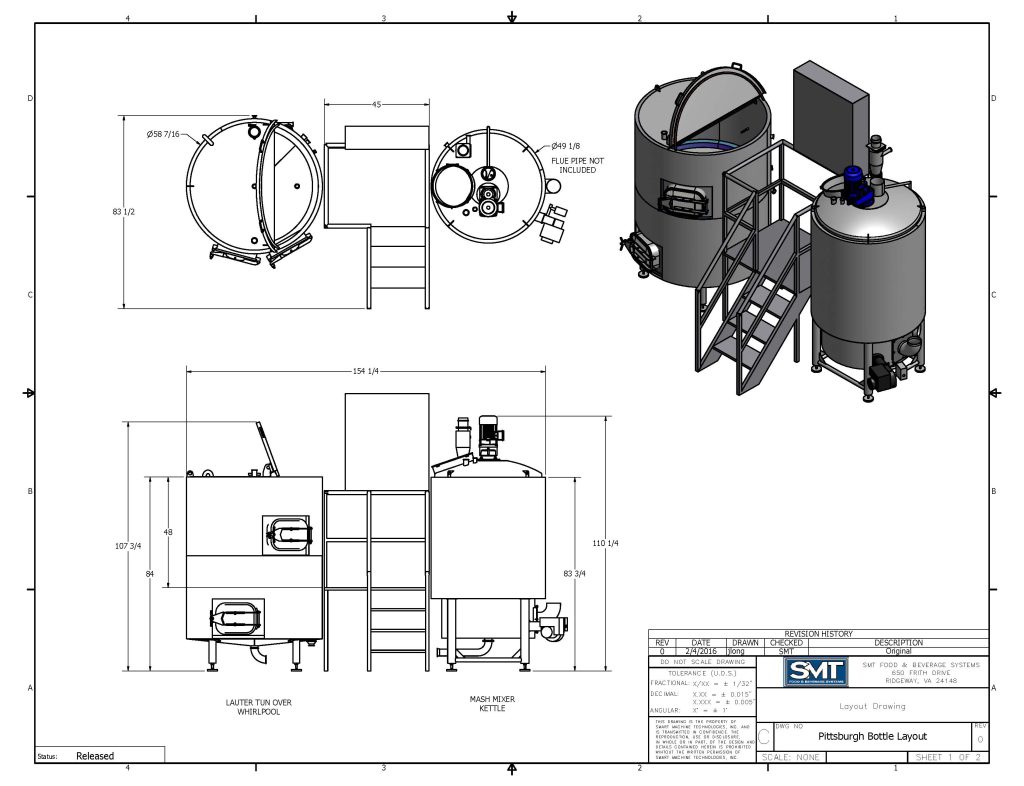

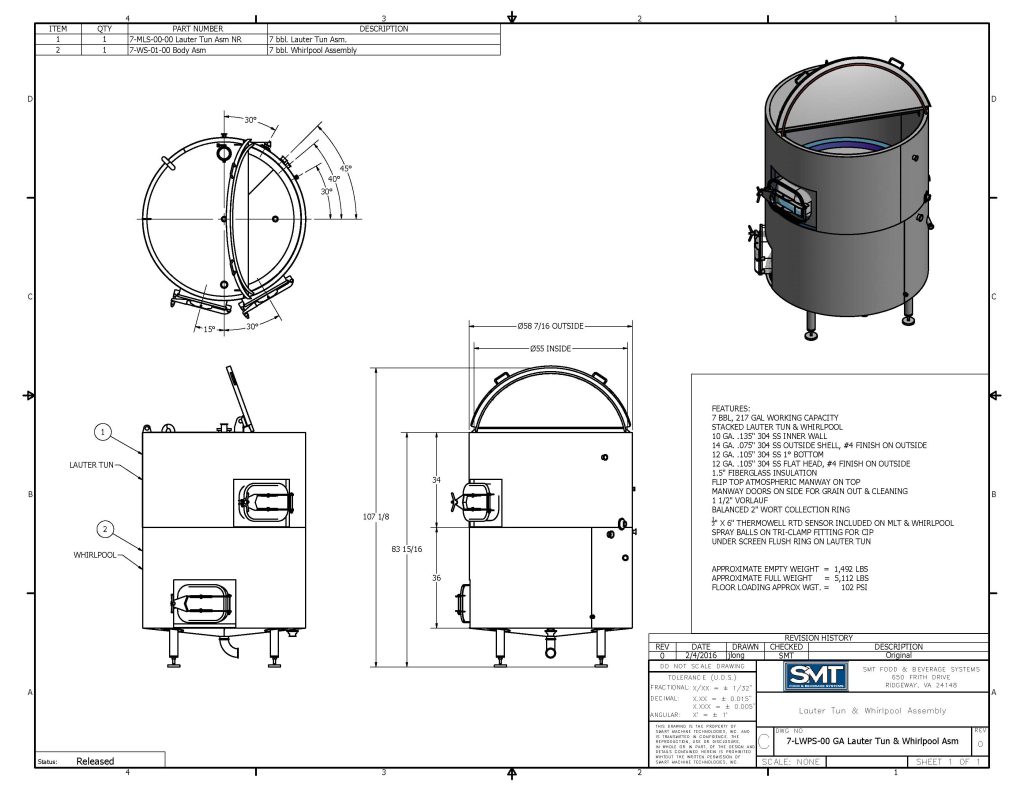

– 1x 7 BBL Lauter Tun: 4×4’ Legs with adjustable footpads. 3/4” thread. *Shell Material t304 2b s/s, Cladding material t304 2B s/s *All weld finish and cladding penetrations are polished and inspected to sanitary grade. *Formed top head, flat bottom, Insulation on sides. *top fittings: Atmospheric manway, 1.5” CIP, sparge piping *Side fittings: Thermowell, 21”x16” manway for spent grain removal *bottom fittings: 5xWort outlets, 93-V wedge-wire false bottom, 1.5” wort collection header *Approximate dimensions: ID=45”, Cylinder Height=56”, Total Height=94”

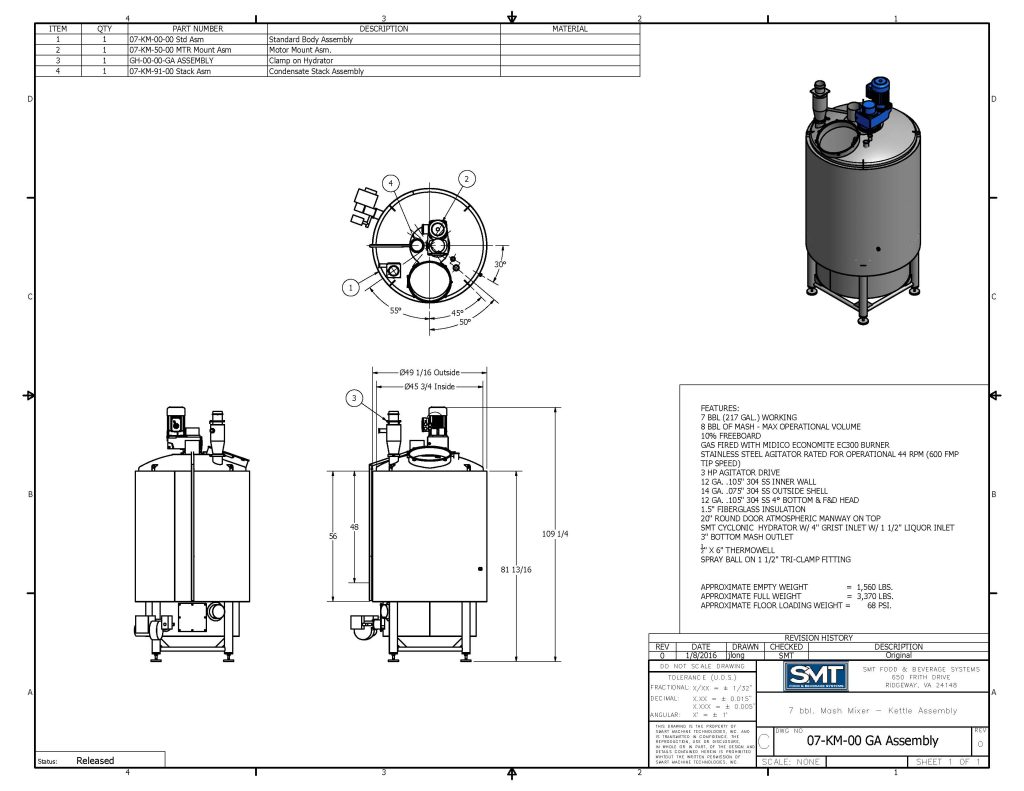

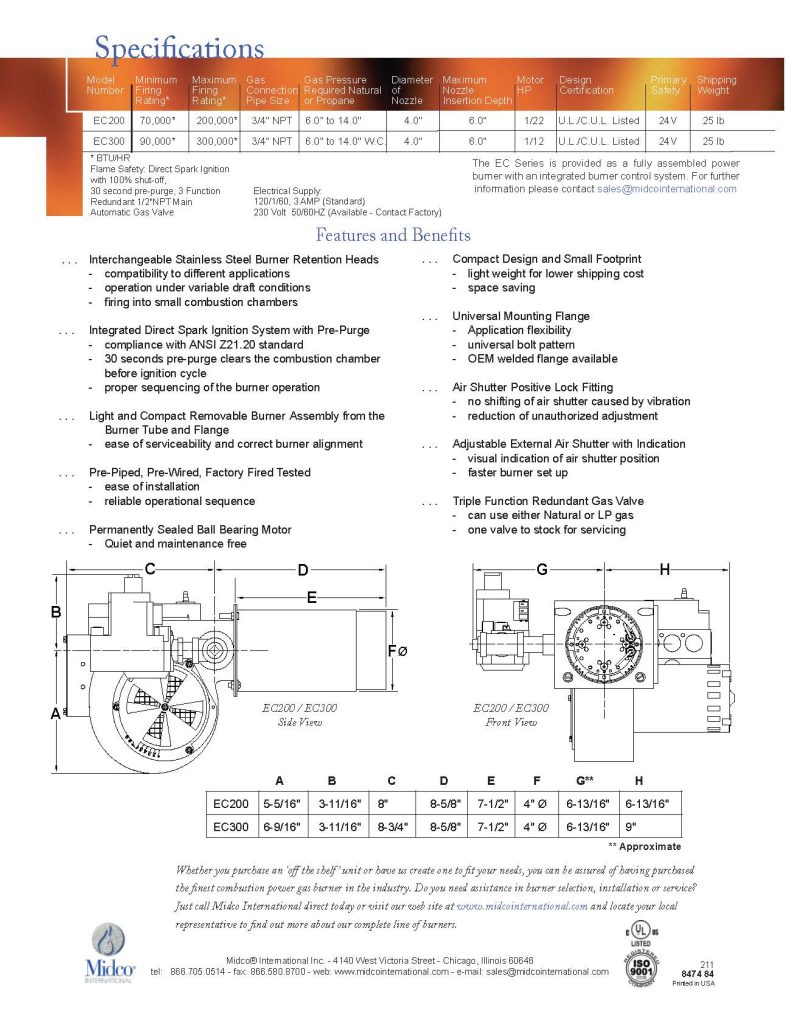

– 1x 7 BBL Direct Fired Brew Kettle / Mash Mixer: 4’ Legs with adjustable footpads. *Shell, Cladding and Bottom material are t304 2b s/s. *All weld finish and cladding penetrations are polished and inspected to sanitary grade. *Formed conical head, 4 degree bottom cone. *1.5” Insulation on sides and bottom. *Top fittings: 8” vapor vent, grist hydrator, 1” water inlet, condensate drain, 18” Atmospheric manway, 1.5”CIP. *Stack and facility venting system sold separately. *Side fittings: wort inlet, thermowell; Bottom fittings: Outlet to mash transfer pump & drain. *Includes independent VFD controlled stainless mash transfer pump. *Approximate dimensions: ID=42”, Cylinder Height=48”, Total Height=72”

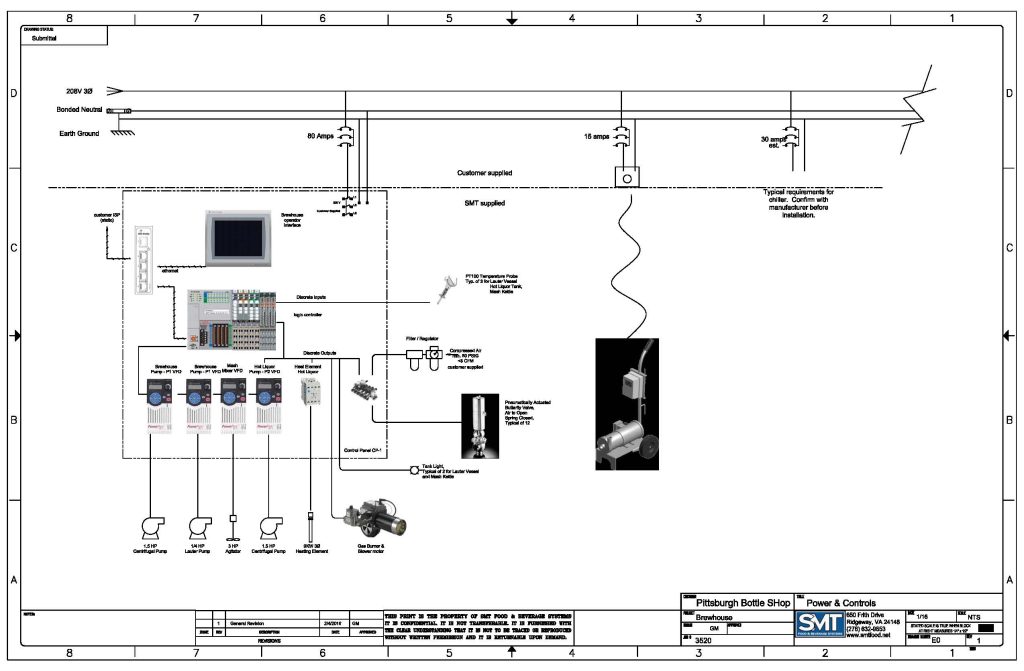

– 7 BBL Brewhouse Process Piping, Controls, Pump, Heat Exchange & Work Aeration Assembly: Process Piping: All sanitary piping is made of T304 s/s, pre-fitted for quality inspection then disassembled for shipping. All fittings, gaskets and s/s butterfly valves are included. Heat Exchanger (QTY 1): Single pass high efficiency plate and frame heat exchanger. Sanitary Design 316 stainless steel plates and connections EPDM/FDA gaskets. Sanitary Tri-clamp product connections. NPT threaded for non-product connections. Efficient heat recovery possible with customer supplied plumbing to hot liquor tank. Work Pump (QTY 1): 1.5 HP VFD stainless pump. Wort Aeration Assembly (QTY 1): Complete with a sanitary stainless steel thermometer, sintered stainless steel aerating stone. 1 ½’ sight glass, shutoff and check valves, quick disconnect. 7 BBL Brewhouse Control Panel (QTY 1): Stainless steel construction, watertight, Nema 4 Cabinet, Single control point for most brewing operations. *1.5” tube frame hold control pane. And up to 3 VFD’s. *Frame mounts to the work platform railings using tube hangers. *Unit comes complete with pump switches, temperature read outs for brewhouse vessels, pre-mounted on work platform. *Solenoid valves not included. 7BBL Brewhouse Work Platform (QTY 1): Stainless steel construction with slip resistant grating. *Handrails on stairs and platform. *Convenient working height for brewhouse vessels. *Control panel can be mounted on the front railing next to the stairs. *Liquor Blending Station can be mounted on the rear hand rail. Liquor Blending system (QTY 1): Temperature indicator and mixing valves allow brewer to adjust brewing liquor temperature. *System includes thermometer and inline thermometer mount, manual valve for hot liquor, manual valve for cooling water, flow meter, and pipe-work combining hot liquor and colling water lines. *Stainless steel tubing and valve to kettle fill, sparge. *Flexible hosing may be used at various connections in line to the grist hydrator. 4” Stainless Steel Grist Hydrator (QTY 1): Combines grist and water entering Mash/Lauter Tun, *T/C connection to Mash/Lauter Tun and T/C water inlet connection 5,000 lb/hr capacity.

– 7 BBL Dedicated Whirlpool Vessel 4×4” Legs with adjustable footpads. 3/4” thread. *Shell material t304 2b s/s, Cladding material t304 2B stainless steel., *All weld finish and cladding penetrations are polished and inspected to sanitary grade., *Formed top head, dished bottom, Insulation on sides. *Top fittings: Atmospheric manway, 1.5: CIP, grist hydrator, liquor blending system. *Bottom Fittings: wort racking port, drain. *Approximate dimensions: ID=42”, Cylinder Height=48:, Total Height=72”

– Masher Mixer Add: VFD controlled low shear mixing paddle and mounted motor.

– Additional Brewhouse Pump Add

– Heat Exchange upgrade to dual stage unit Add

– (2) Interior brewhouse vessel illumination Add

– Clear vessel manway Add

– Lauter Tun under screen water flushing system Add

– Combination Brewhouse Vessel Custom Engineering w/3 Stack System: Top=Lauter Tun; Mid=Elec HLT; Bot=Whirlpool Add

– (3) Upgrade to #4 finish on all brewhouse vessel cladding

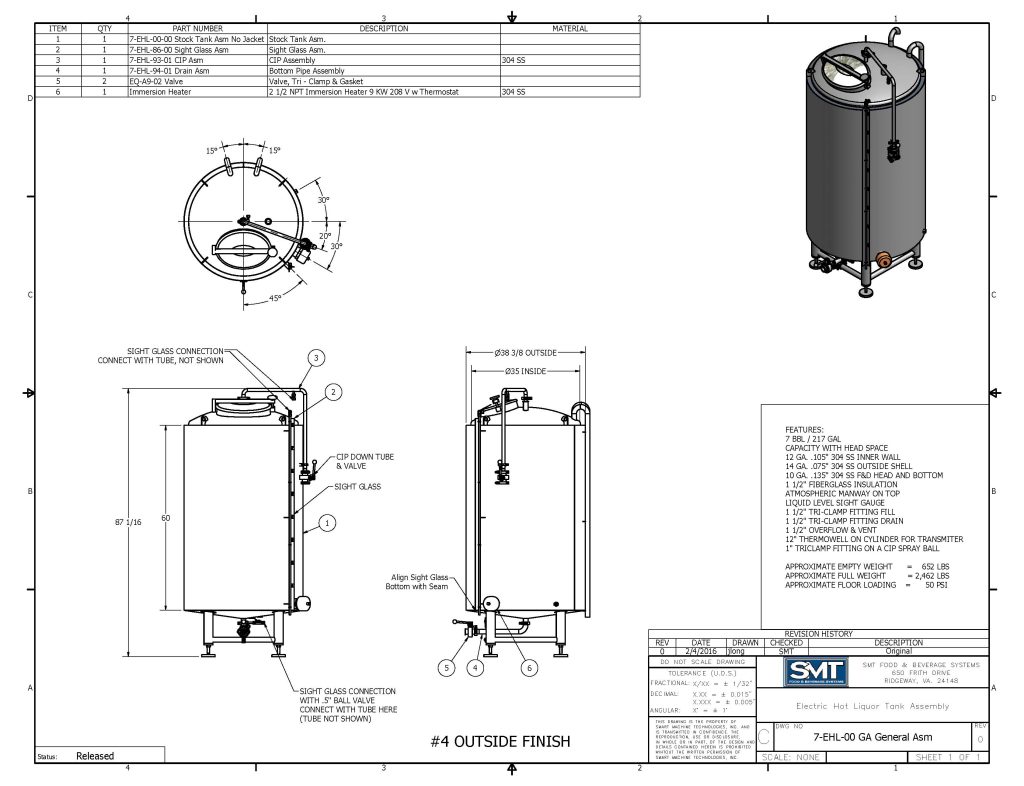

– 7 BBL Electric Hot Liquor Tank & 1.5 HP Sanitary Pump 4×4” Legs with stainless steel footpads. *Shell material t304 2b s/s Cladding material t304 #4 stainless steel. *All weld finish and cladding penetrations are polished and inspected to sanitary grade. *Shallow cone top, Shallow cone bottom. *Insulation & cladding on sides and bottom. *Top fittings: 18” Atmospheric manway, CIP c/w 1” side arm & Sprayball, 1” water inlet. 1” Recirc inlet, 1” recovery inlet *Side fittings: Liquid level sight tube. *Bottom fittings: 1 ½’ Drain, thermowell, 1.5 overflow *1.5 HP Wash-down motor with s/s pump head & piping manifold.

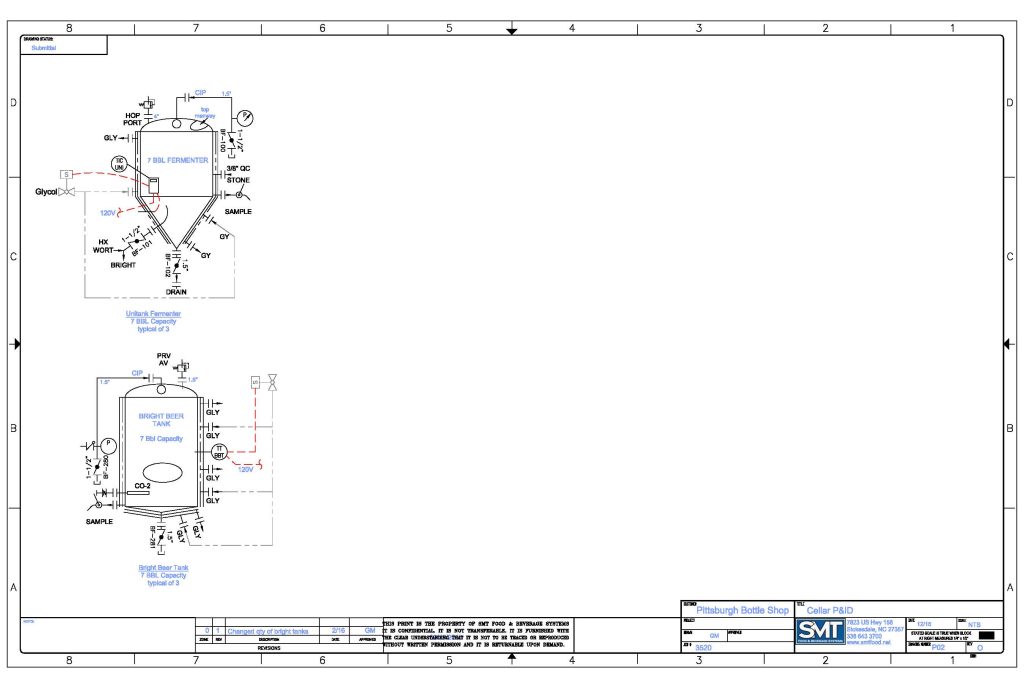

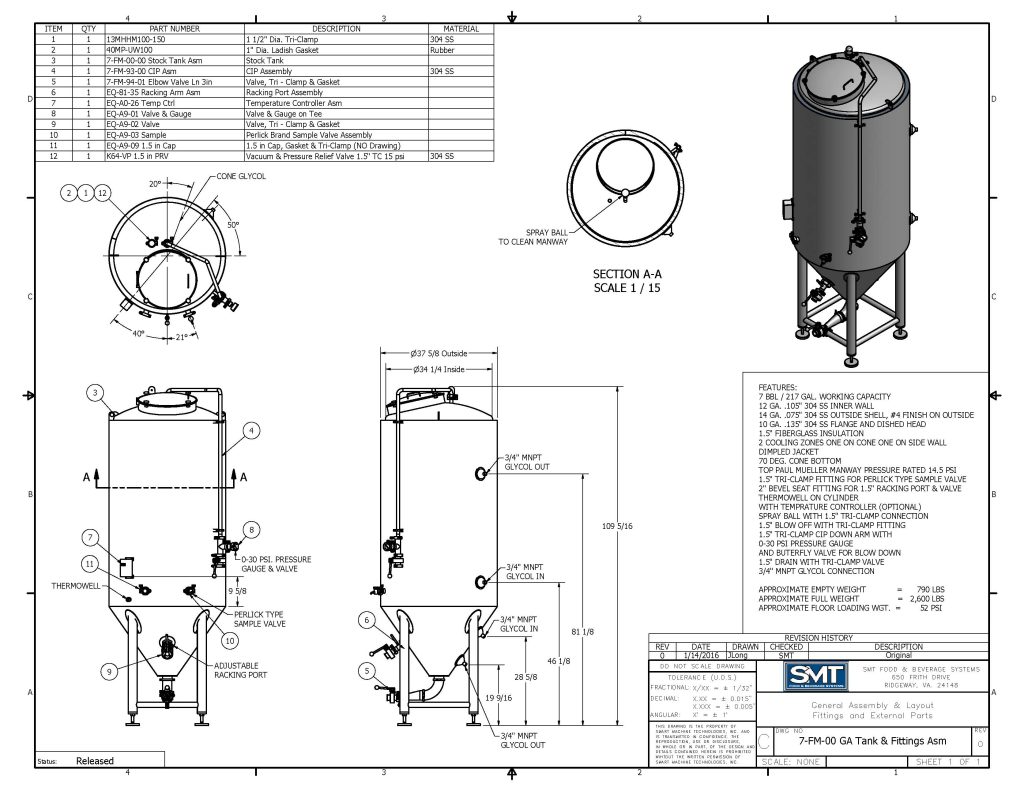

– (3) 7 BBL Unitank Fermenters *Total Vol= 278 gal. Head Space= 28% OD= 44” Total Height = 81” Pressure Rating = 14.9 psi *Construction: 304 stainless, all internal welds polished and inspected to sanitary grade. *External Cladding: 14 gauge with 2B finish. *Inner Structure: 12 gauge 70 deg cone, 12 gauge inner sidewall, 12 gauge dished head. *Top Head Fittings: 1.5” pressure relief valve on a 4” tri-clamp fitting for hop dosing. *CIP: 1.5” arm with 2.5” sprayball, pressure gauge and BF valve. *Alfa-Laval (or equal) “in-swing” sanitary manway. *Cooling Jackets: dimple plated and baffled; (1) sidewall and (1) cone. *Insulation: 1.5” fiberglass on sidewall & cone *Jackets sized to cool the working vol from 65F to 34F in 24 hours using a glycol inlet temp,. at 30F. *Sidewall Fittings: 2” TC port with 1.5” swivel racking arm on cone, 1.5” TC port & sample valve, *(2) ½’x6’ FNPT thermowells positioned on cone & cylinder. *Outlet: 1.5” TC with extension arm & BF valve. *Lets: 4 x leg stands with adjustable feet.

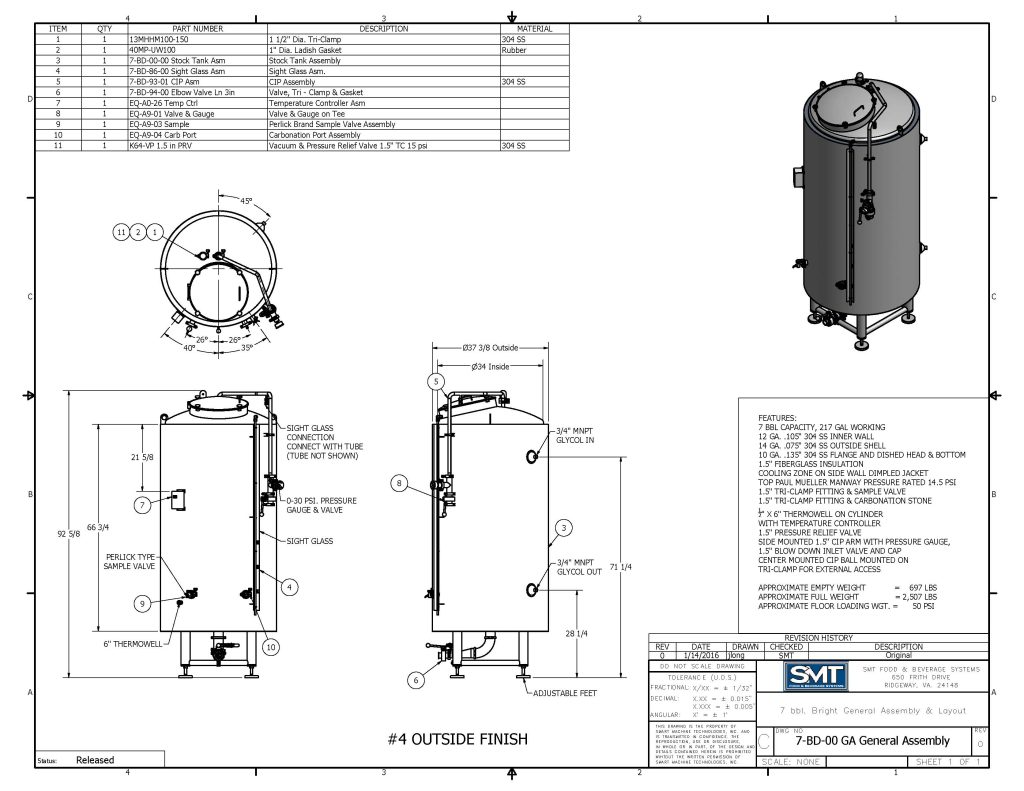

– (3) BBL Jacketed Brite Beer Tanks Total Vol=263 gal. Head Space= 21% OD=39” Total Height=83” Pressure Rating= 14.9 psi *Construction: 304 stainless, all internal welds polished and inspected

to sanitary grade. *External Cladding: 14 gauge with 2B finish. *Inner Structure: 12 gauge dished bottom, 12 gauge inner sidewall, 12 gauge dished head. *Top Head Fittings: 1.5” pressure relief valve. *CIP: 1.5” arm with 2.5” sprayball, pressure gauge and BF value. **Alfa-Laval (or equal) “in-swing” sanitary manway. *Cooling Jackets: dimple plated and baffled; *Insulation: 1/5” fiberglass on sidewall *Sidewall Fittings: 1.5” TC port & sample valve, ½”x6” FNPT thermowell, 1.5” port & carb. Stone *Outlet: 1.5” TC with extension arm & BF valve *Legs: 4 x leg stands with adjustable feet.

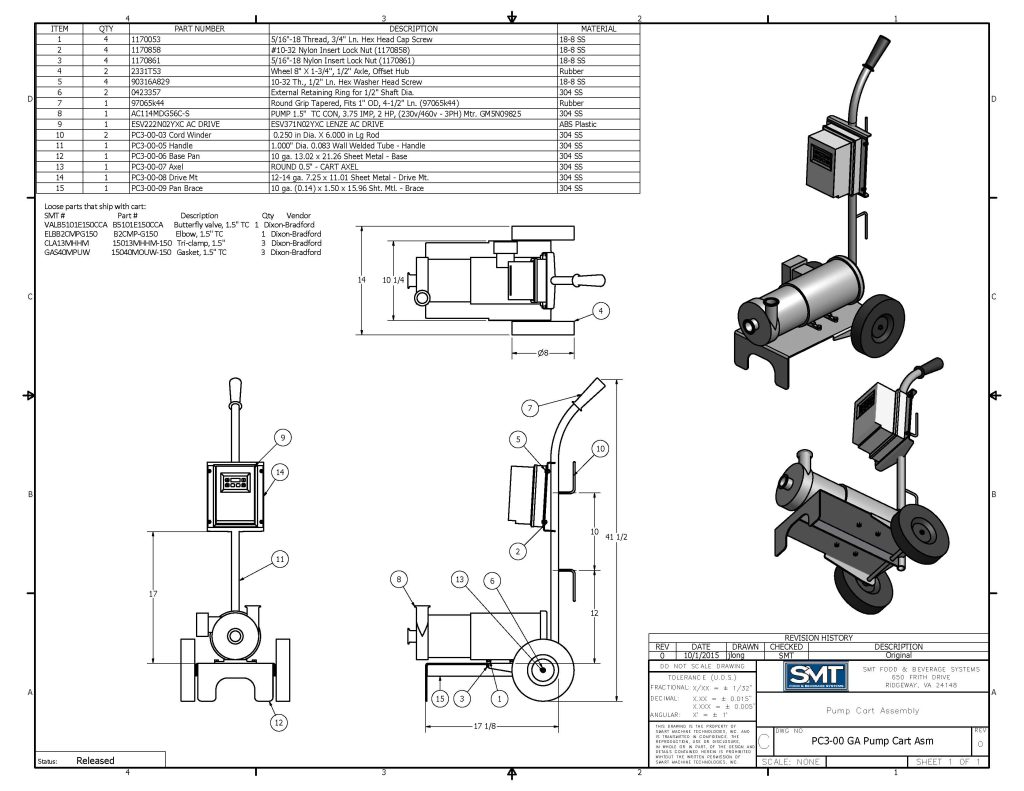

– Portable Pump For CIP & Cellar Transfer – 1.5’ butterfly valve. *1.5” elbow. *1.5” clamps and gaskets. *NOTE – Chemical reservoirs are not included in this package.

– Advanced Controls & Automation Package: Allen-Bradley Custom Brewhouse Management Automation & Process Control Package: Includes air actuated valving package on the brewhouse, programmable logic, integrated liquor blending, monitor (recently replaced) & adjust cellar controls remotely.