Late Additions!

- 2014 Ilapak Delta 4000 LDR/3SSC Horizontal Flow Wrapper, S/N 640290009, with Walking Beam Long Dwell Head with Gusset Bag Attachment, Automatic Smart Belt Feeder, Print Registered Film, with Web Directional Zipper Applicator, and Unwind Unit with Punching Device (Pancake Line #5)

- 2014 Ilapak Delta 4000 LDR/3SSC Horizontal Flow Wrapper, S/N 640290007, with Walking Beam Long Dwell Head with Gusset Bag Attachment, Automatic Smart Belt Feeder, Print Registered Film, with Web Directional Zipper Applicator, and Unwind Unit with Punching Device (Waffle Line)

- 2014 Ilapak Delta 4000 LDR/3SSC Horizontal Flow Wrapper, S/N 640290008, with Walking Beam Long Dwell Head with Gusset Bag Attachment, Automatic Smart Belt Feeder, Print Registered Film, with Web Directional Zipper Applicator, and Unwind Unit with Punching Device (Waffle Line)

Frozen Waffle Production Lines

- (4) HAAS Waffle Lines with Model SOWN 80 S/S Oven Systems. Complete with Square, Round & Rectangle Mold Sets, Depositors, S/S Exhaust Systems & Digital Controls. Gas Fired.

- (8) Mold Sets for HAAS Waffle Lines & Assorted Spare Components

- Spiral Freezers & Packaging for Waffles Listed Under Separate Headings

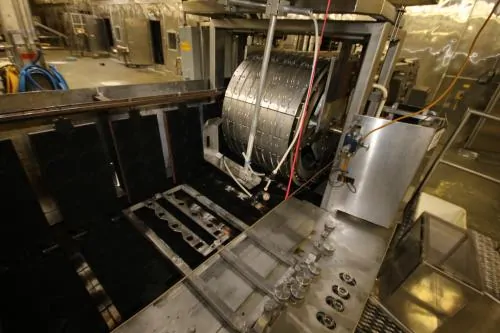

French Toast Production Lines

- (4) Complete French Toast Lines Including Gas Grill Systems, Stein APB Batter Applicators, Depositors, Extensive Late Model Conveyor Systems, Controls, S/S Hoods and Related.

- (2) 2013 UBE Hartman Bread Slicers, Model 1900, S/N C950 & C951, Including Landing Conveyor Systems.

- Systems Fed Into 2011 GEA Spiral Freezing System & Packaging Systems Listed Under Separate Headings.

Pancake Production Lines

- (2) Complete Dejersey Pancake Production Lines Including Gas Griddles, S/S Hoods, Exhaust Systems, APV Positive Pumps & Controls

- (2) 5 Pass All S/S Cooling/Freezing Conveyors, Approx. 8’x40′ with Additional Conveyor Systems & Related Items Including VFD Speed Controllers

- Extensive Late Model Conveyor Systems & Pancake Packaging Listed Under Separate Headings.

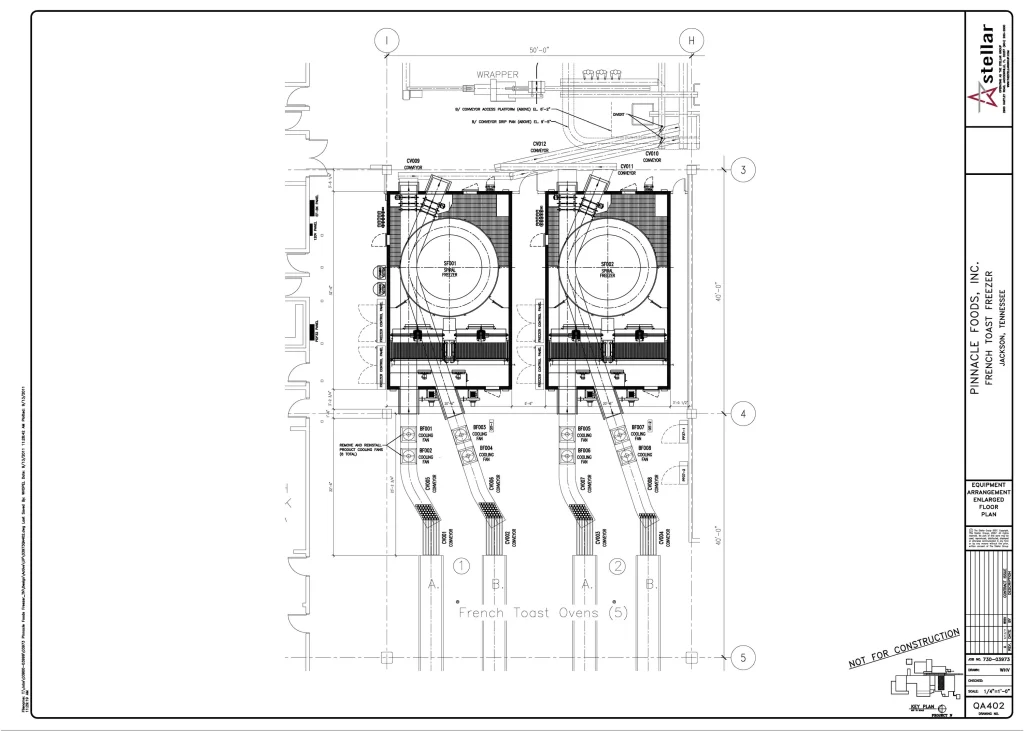

GEA 2011 Spiral Freezers

- (2) GEA 2011 Spiral Freezers, S/N 06176B-001-1-01 & 2. Beautifully Equipped with Onboard CIP Systems, Controls, & Conveyor Systems In & Out. 32 in. Wide Belt with 5 in. Spacing. Click Here for a PDF of Systems.

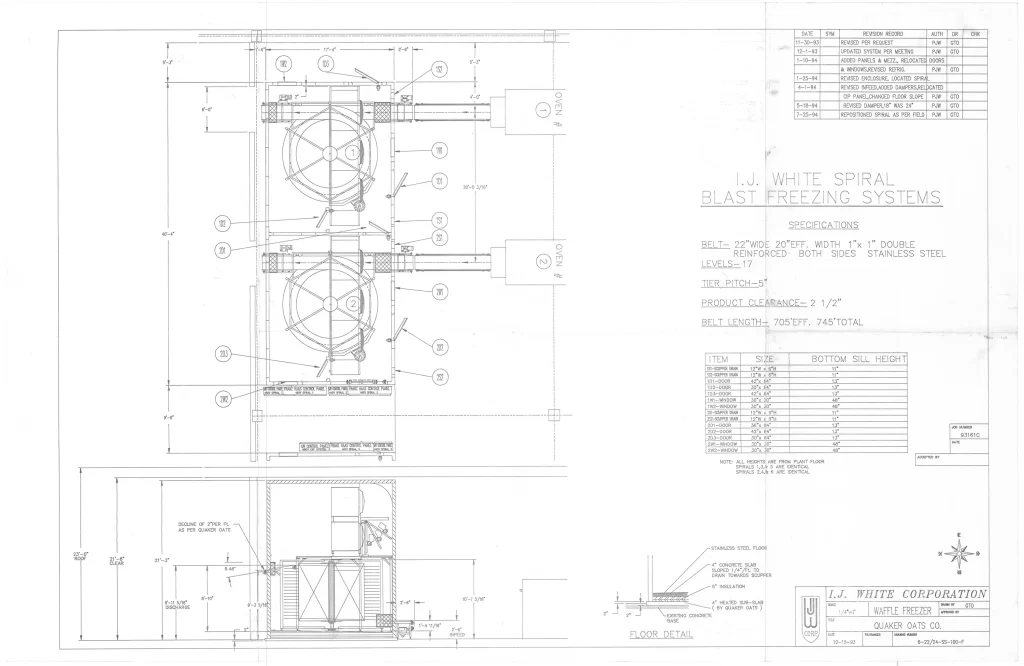

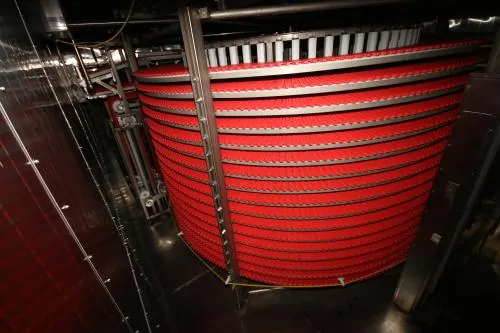

IJ White Spiral Freezers

- (6) IJ White Spiral Freezers. Most Equipped with 20 in. Wide Regal Conveyor Belt, Each Equipped with Six Fans of Freezer Blowers Mounted Above the Spiral. 2.75 in. Belt Spacing. Refrigeration and Upgrades Installed in 2011.

Packaging Lines & Additional Equipment

- Forpak 8-Lane Product Stackers & Accumulating Systems

- Wrappers Including:

- Campbell Revolution Wrapper, S/N 6673-0385

- 3 FMC Flow Wrappers including WS-2D-II

- ADDITIONAL WRAPPERS TO BE ADDED

- (3) Fallas Corrugated Lines Including Model R400 Packers with Case Formers, Sealers, Coders & Conveyors

- Kliklock Cartoner, Model HS, S/N 3133 with Nordson Glue

- Additional Packaging Including:

- (10) Metal Detectors and Check-Weighers by Safeline, Micromate and Mettler

- (2) Scantrac X-ray Inspection Units

- (3) Ryerson Spiral Case Elevators

- Large assortment of Coders, Case Sealers, Case Conveyors, S/S Crossovers and Related Items

Product Conveyor Systems

- Dozens of Late Model S/S Product Conveyors. Assorted Lengths with Drives, Diverters, Stands & Combiners. Most 8″ and 12″ W (More Lengths to be Detailed Soon) Including Case Conveyor Systems.

Mix & Blend Systems

- 2013 Marion Mixer S/S Blender, S/N SP4-4272

- Additional Marion Mixer (Details Coming Soon!)

- (2) Kason 36″ Powder Sifters with Dust Systems

- (2) Batter Mix and Blend Systems each Equipped with Powder Feed and S/S Processor with Related Pumps, Valves and Controls.

- 2011 Installation of Batter Mix & Blend System with (2) Walker 100 Gallon Combination Liquefier Processors and (2) Walker 150 Gallon Processors with Scrape Agitation. All units Mounted on Load Cells with Pumps, Valves and Controls.

- Additional Batter Blend System with Feldmeier 300 Gallon Jacketed Processor

S/S Silos & Tanks

- Mueller 12,000 Gal. S/S Silo, M/N DF, S/S Exterior, Dome Top

- Mueller 7,500 Gal. S/S Silo, S/S Exterior

- Mueller 6,000 Gal. S/S Silo, S/S Exterior

- (2) Indian 6,000 Gal. S/S Single Wall Vertical Silo

- (2) Cherry Burrell 4,000 Gal. S/S Vertical Tanks, M/N SVW

- (2) Cherry Burrell 6,000 Gal. S/S Horizontal Tanks, M/N GHW with S/S Front and Dual Vertical Agitators

- (2) Cherry Burrell 7,000 Gal. S/S Horizontal Tanks, with S/S Front and Vertical Agitation

CIP Systems

- (2) S/S 300 Gal. Tanks Skid Mounted CIP System, with Alpha Laval Pump, S/S Shell and Tube Heat Exchanger, Alfa Laval Air Valves, Allen Bradley PanelView Plus 1000 Touchscreen Controls

- (3) S/S 300 Gal. Tanks Skid Mounted CIP System, Rectangular Tank Design, with Alfa Laval 15 hp Pump

- Cherry-Burrell S/S Rectangular 200 Gal. CIP System, with (3) Dividers, with Ampco 15 hp Centrifugal Pump, WCB Air Valves, 2-Tank S/S Chemical Holding Tanks, Overall Dims.: 72″ L x 36″ W x 53″ H

Process Support Systems

- 2011 Clayton Skid Mounted Steam Boiler, M/N EC-254-1-DZ, S/N 25047

- Clayton Skid Mounted Deaerator System with Water Softener

- Tigerflow Skid Mounted Boiler Feed System, with (3) Pumps, (3) Allen Bradley VFDs and Red Loin Touchscreen Controls

- Vertical 2,000 Gal. Hot Water Tank

- 2011 Chester Jensen ALL S/S Plate Water Chiller, M/N B-8-01-4-32, S/N 1121-P, with 2011 Phillips Accumulator,

- Alpha Laval Skid Mounted Plate Heat Exchanger, M/N M10-MFG, S/N 30113-9J527

Seafood Production Assets

- (4) Nothum VC-40 Versa Coat Breader Applicators (40”)

- (3) Nothum BP-40 Batter Pro Batter Applicators (40″)

Additional Equipment

- APV S/S Plate Heat Exchanger, M/N R51, S/N 25703, with (2) Dividers and (65) S/S Plates

- (3+) Jet Spray S/S Wash Troughs, 75″ L x 20″ W x 17″ D

- (50+) WCB and Other S/S Air Valves

- (500+) S/S Clamps

- Full Receiving Bay

- (15+) APV and Tri-Clover Positive Displacement Pumps and Other Centrifugal Pumps

- 1000s of Ft. 1-1/2″-3″ S/S Piping, Some Piping is Jacketed