CUSTOM HDPE & PET BLOW MOLDING DEPARTMENT

HDPE BLOW MOLDERS

- APS 6-Head Blow Molder, M/N RSM 3.5-6, S/N 20000122, Includes Bottle Cooling Fan & Conveyor, with Allen Bradley PanelView 1000, NEW Light Weight Swing Arm, with Cuttler Hammer Safety SwitchAPS Electric Schematic Impact Trimmer, with Allen Bradley MicroLogix 1500 3-Slot PLC, 480 Volts, 3 Phase, Includes Allen Bradley PanielView 300& Blower, with Siemens Safety Switch & Siemens Adjustable Frequency Drive, 5,132.7 Hours (Line 6). Sets of Hogle Gallon Molds, M/N 349

- Uniloy 6-Head Blow Molder, M/N 350R2, S/N 5080, Includes Bottle Cooling Fan & Conveyor, 8″ Centers Running Gallon Bottle, with Allen Bradley PanelView 1000 Touchscreen, with Upgraded Air Flow with Tank (2 yr. Old Upgrade), with Extended Shot Cylinder, with Cuttler-Hammer Safety Switch, with Uniloy Trimmer, M/N 10041, S/N 5080T, 460 Volts, 3 Phase, with Siemens PLC Simatic S7200, 12,024.4 Hours (Line 5) (NOTE: Includes Change Parts to Turn Blow Molder Into 8-Head Machine). Sets of Uniloy 1/2 Gallon Molds, Refurbished in 2018 by Mid-America

- Plastics USA Corp. 6-Head Blow Molder, M/N Liberty 3506, S/N 89007, New Air Barrel & Screws in 2018, Includes Cooling Conveyor, Uniloy Pick N’ Place Trimmer, with (6) Vacuum Heads, 63,932.3 Hours (Line 7). Sets of Hogle HDPE Gallon Mold Sets, M/N 70219, S/N 550A

- Uniloy 4-HEAD HDPE Blow Molder, M/N 350R2, S/N 4041, with Upgraded Heat Controls, Includes Cooling Conveyor, Direct Load Double Load Trimmer, with Extended Beam, with NEW GRX Heat D, Includes General Electric Transformer, 4,675.7 Hours (Line 2). Sets of Hogle Squat Quart Molds, M/N RSM096, S/N 6A

- Uniloy 4-Head HDPE Blow Molder, Upgraded in 2013: Barrel, High Output Screws, Allen Bradley PLC, Like NEW Weg 30 hp Hydraulic Unit, with 1735 RPM Motor, NEW Rebuilt Clamp within Last 2 Yrs., Includes Bottle Cooling Fan & Conveyor, Uniloy Trimmer, Includes Federal Pacific Transformer, Cat.No.-FH118CFMD with Square D Safety Switch, with Reliance Electric AC Drive SP600, 9,562.7 Hours (Line 3). Sets of Uniloy Gallon Molds, M/N 80552, S/N 107A & 107B, Referbished by Mid-America

- Uniloy 4-Head HDPE Blow Molder, M/N 4011, S/N 4011-2311, Everything Upgraded in 2013, High Output Screw Installed, Controls Upgraded in 1998, 2010 Air Barrel Upgrade, NEWER Koyo Direct Logix 06 RC PLC Controls, with Spin Trimmer, with Dura 50 hp Pulse VFD, 5,940.5 Hours (Line 10). Sets of Hogle 8 oz. Single Serve Molds, M/N HSM0104-4

LARGE ASSORTMENT OF HDPE BLOW MOLDER PARTS

- Uniloy Trimmer, M/N 10041, 460 Volts, 3 Phase, S/N 2423R, with Allen Bradley DTAM Plus, with Allen Bradley 4-Slot PLC, with SLC 5/04 CPU Inserts, with Leak Detection (NOTE: Formerly Operated with APS Blow Molder)

- NEW Large Assortment of Blow Molder Parts, Includes NEW Large Assortment of Castle Mold & Tool Shear Steel, High Flow Blow Pin Bodies, NEW Large Assortment of Uniloy Shear Steel, High Flow Blow Pin Bodies, Blow Pins, and Other Present NEW Inventory, Call our Office for Complete List 412-521-5751

- NEW S/S T-Blocks, with (4) NEW Block Style Gallon T-Blocks, 2-with Neck Inserts (NOTE: For Light Weight Bottles)

- Wide Assortment of 1/2 Gal. and 1 Gal. Molds – Check Catalog for Details!

REGRIND ROOM

- Foremost Grinder, M/N HD-5C, S/N 40579, 3-Blade Design, with Lincoln 30 hp Motor, 1775 RPM, 230/460 Volts, 3 Phase, Aprox. 14″ L x 18″ W Feed Throat, with Regrind Transfer Chutes. Carbon Steel Regrind Holding Bin on Casters, with Like NEW Top Mounted Cyclones, Bottom Discharge

- Foremost Grinder,3-Blade Design, with Lincoln 30 hp Motor, 1775 RPM, 230/460 Volts, 3 Phase, Aprox. 14″ L x 18″ W Feed Throat, with Regrind Transfer Chutes. AEC Whitelock Hopper, with Like NEW Top Mounted Cyclones & Vacuum Loader, Bottom Discharge

- Foremost Grinder,M/N DB-5, S/N 38028, 3-Blade Design, with Lincoln 5 hp Motor, 3485 RPM, 230/460 Volts, 3 Phase, Aprox. 14″ L x 18″ W Feed Throat, with Regrind Transfer Chutes. Carbon Steel Regrind Holding Bin on Casters, with Like NEW Top Mounted Cyclones, Bottom Discharge

- Conair Franklin 3-Compartment Auto-Weigh Self Loading Gravimetric Blender, with Hopper Dryer

- Conair Franklin 2-Compartment Auto-Weigh Self Loading Gravimetric Blender, with Hopper Dryer

- Conair Franklin 1-Compartment Auto-Weigh Self Loading Gravimetric Blender, with Hopper Dryer

- Large Assortment of Vacuum Pumps

(2) COMPLETE PET BLOW MOLDING LINES

- SIDEL PET BLOW MOLDING MACHINE, M/N SB06/10

- Sidel PET Blow Molding Machine, M/N SB06/10, S/N 350, with 6-Heads with Preferential Heating, Production Output of 13,500-63,000 Bottle Per Hr., Runs Bottle Sizes of 1-3.5 Liters, Capacity Speed of 7,000 Bottles Per Hr., Neck Diameter of 28mm, Pitch to 60mm, with Pre-Foam Orientation Conveyor, with Control Panel

- Sidel Pre-Form Elevator Conveyor with Hopper, Hopper Dims.: Aprox. 70″ L x 40″ W x 31″ Dia., Aprox. 140″ Tall x 12″ W Conveyor with Flights

- IMCS Dumper, with Aprox. 42″ L x 47″ W x 55″ H Dump Compartment, 440 Volts, 3 Phase

- Dyco Autopack/Stacker, M/N 3721, S/N 37-125-1299, with Allen Bradley 9-Slot PLC, M/N SLC 5/03 CPU, with 30″ W Discharge Conveyor, with Dyco Pick and Place Vacuum Arm with (8) Vacuum Heads (25 Bags Per Hour)

- Versa Conveyor Power Conveyor, Aprox. 13′ L

- Aprox. 72′ of S/S Product Conveyor, with 3″ W Chain, with Guide Rails and Drives

- Platform with Stairs & Handrails, Overall Dims.: Aprox. 122″ L x 79″ W x 74″ H

- ELECTRA FORM INC. 2-HEAD PRE-FORM PET BLOW MOLDER

- Electra Form Inc. 2-Head Pre-Form Blow Molder, M/N RSB-2000, S/N 53423, with Allen Bradley 10-Slot PLC, M/N SLC 5/03 CPU, with Pre-Form Infeed, 460 Volts, 3 Phase

- Caidlin S/S Elevator Conveyor with Hopper, M/N T Feeder, S/N 36-3312-97, 120 Volts, 1 Phase, Hopper Dims.: Aprox. 42″ L x 35″ W x 24″ D, Stand Aprox. 90″ Tall

- IMCS Dumper, with Aprox. 42″ L x 47″ W x 55″ H Dump Compartment, 440 Volts, 3 Phase

- Plastic Process Equipment Power Conveyor, Aprox. 12′ L x 18″ W Belt, Stands Aprox. 85″ Above Floor

- Concept Systems Inc. Bagger, with Seal Arm, Aprox. 33″ W Discharge, Formerly Bagged 12 oz., 16 oz., and 32 oz. Round Bottles

- Dyco S/S Product Conveyor, Aprox. 66′ L x 3″ W Chain, with Drives & Guide Rails

COMPLETE BAGGING FLOOR

- Dyco Single Infeed Fully Automatic Bagger, M/N 3720, S/N 37-087-1297, with Wrap Station & Discharge Conveyor, with Allen Bradley 10-Slot PLC, M/N SLC 5/03 CPU, and 30″ W Discharge Conveyor

- Dyco Bottle Autopack/Stacker, M/N ORD12227, with Allen Bradley 10-Slot PLC, with SLC 5/03 CPU Inserts, with Allen Bradley PanelView 550, with 30″ W Discharge Conveyor, with Dyco Pick and Place Vacuum Arm with (8) Vacuum Heads (25 Bags Per Hour)

- D & S Bottle Automatic Packer/Stacker, with Allen Bradley MicoLogix 1500 6-Slot PLC, with (8) Head Vacuum Pick Arm, with 36″ W Discharge Conveyor

- Automatic Inspection System Bagger, Job. No. 1802-1, S/N 1153-91, with (3) Allen Bradley SLC 100 Programmable Controllers, with S/S Discharge Table & Cut Arm

- Dyco Semi-Automatic Bottle Bagger, M/N 2020, S/N 20-628-0997, with Allen Bradley 500 Programmable Controller, with S/S Discharge Table & Cut Arm

- Automatic Inspection System Bagger, M/N 268-GD, S/N 1035-87, with (2) Allen Bradley SLC 100 Programmable Controllers, with S/S Discharge Table & Cut Arm

- With Labeling System and Large Assortment of Conveyor (Both Product and Jug Conveyors)

BLOW MOLDING DEPARTMENT SUPPORT

- HIGH PRESSURE AIR SYSTEMS

- Belliss & Morcom 250 hp High-Pressure Reciprocating Compressor, M/N VH15H3N, S/N 9082, Stroke 165.1 MM, 750 Max. RPM, 45.5 Bar G Pressure, with Teco 1780 RPM Motor, 575 Volts, with SPX High Pressure Air Dryer, M/N HPET-1.5-700 WC, S/N WHP157004600311008, with (2) Control Panels, with Safety Switch, and Vertical Air Receiver, Mounted on Skid (68,450.5 hrs)

- Belliss & Morcom 150 hp High-Pressure Reciprocating Compressor, M/N VH9H3N, S/N 8581, 985 RPM, 40 Bar Pressure, with Toshiba 1780 RPM Motor, 230/460 Volts, with Hankison Air Dryer, M/N HPRD-2, with (1) Control Panel, and Vertical Air Receiver, Mounted on Skid (22,983 hrs)

- CHILLERS & AIR COMPRESSION SYSTEMS

- Trane 140 Ton Water Cooled Rotary Chiller, M/N RTWD 140F 2A01 A1A1 AA1A 1A1X 1B0A 1000 0000 000A02001 0BD0, S/N U08G00133, Design Pressure: 300 High Side/200 Low Side, 460 Volts/60 Hz/ 3 Phase, with Siemens Safety Switch, Mounted on Skid

- Trane 100 Ton Water Cooled Rotary Chiller, M/N RTWA100AYE01C3COWN, S/N U00006332, Design Pressure: 450 High Side/300 Low Side, 200 Volts/60 Hz/ 3 Phase, with (2) Siemens Safety Switches, with (2) Powertran Transformers, Mounted on Skid

- Trane 80 Ton Air Cooled Rotary Liquid Chiller, M/N RTAA0804XJ01A3DOB, S/N U98F01408, Design Pressure: 450 PSI High Side/300 PSI Low Side, 460 Volts/60 Hz/ 3 Phase,

- Gardner Denver 75 hp Rotary Screw Air Compressor, M/N ELECTRA-SAVER II, S/N U16808, 460 Volts, 1775 RPM Motor

- Gardner Denver 75 hp Rotary Screw Air Compressor, M/N EBMOLC, S/N U14364, 460 Volts, with Weg 1785 RPM Motor

- Gardner Denver 75 hp Rotary Screw Air Compressor, M/N EBMOLC, S/N M66769, 460 Volts, 1775 RPM Motor

- Gardner Denver 50 hp Rotary Screw Air Compressor, M/N ECH0JG, S/N M60392, 460 Volts, with Lincoln 1782 RPM Motor, 230/460 Volts

- ZEKS Water Cooled Dryer, with 66″ Long Tube, Mounted on Skid, with ZEKS Vertical Filter Housing, M/N 1100HDF, S/N 97386, Design Press.: 150 PSIG @ 300 F, with (2) Vertical Air Receiving Tanks

FLUID MILK OPERATION

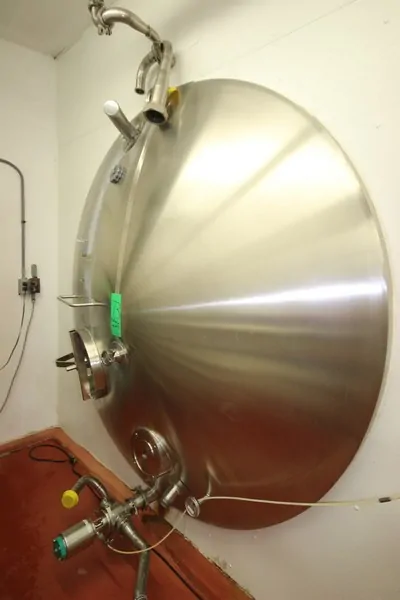

(2) S/S SILOS & MILK RECEIVING

- DCI 30,000 Gal. S/S Jacketed Silo, S/N 92-PH-45133B, with Side Mounted Bottom Agitation, with Reulance 6.23/3.125 hp Motor, 460 Volts, 3 Phase, with Tri-Clover Air Valve, with S/S Alcove, with Siemens Safety Switch & Panel, with King Gage Level Sensor, with Digital Read Out, with Tri-Clove S/S Air Valve, Aprox. 12′ Dia. Silo, with Ladder & Top Man Platform, with External Ammonia Accumulation Tank, Painted Exterior

- St. Regis 15,000 Gal. S/S Jacketed Silo, S/N 3217, with Side Mounted Bottom Agitation, with 2 hp Agitation Motor, 208-230/460 Volts, 1125 RPM, with Tri-Clover Air Valve, with S/S Alcove, with Raloy Outlet Valve Panel, with The King Gage Level Sensor, with Tri-Clover S/S Air Valve, Aprox. 12′ Dia. Silo, Painted Exterior

- APV S/S Plate Press, M/N CR3, S/N 23128, with Single Section with (73) Plates, Overall Dims.: Aprox. 84″ L x 31″ W x 83″ H

- Creamery Products Co. 3-Section S/S CIP System, S/N 128, with S/S Balance Tank, with (1) 7.5 hp Centrifugal Pump, with Baldor 3520 RPM Motor, with (1) 10 hp Centrifugal Pump, with Vanguard 2026, with Associated Valving and Piping, Mounted on Mild Steel Skid

- Waukesha 10 hp Positive Displacement Pump, M/N 130, S/N 15936795, with 3″ Clamp Type Inlet/Outlet, 1755/735 RPM, Mounted on Skid

APROX. 3,000 GPH HTST SYSTEM & MILK SEPARATION

- APV 4-Section S/S Plate Press, M/N R565H/200, S/N 21001, with (173) S/S Plates

- Gaulin S/S Homogenizer, Type 5240MC4525, S/N 8694379, with 3-Pistons, with Pressure Gauge

- 4-Pass S/S Holding Tube, with Ladish Flo-Diversion Valve, M/N 262-121D, S/N 181300, 50 PSI Max. Valve Air Supply, 220 Volts, with S/S Panel, with Square S/S Balance Tank

- HTST 3-Tank CIP System, with (1) Aprox. 250 Gal. S/S Jacketed Tank, with (1) Aprox. 270 Gal. S/S Single Wall Tank, with S/S Balance Tank, with Ampco Aprox. 7.5 hp Centrifugal Pump, Type ZC, with 2-1/2″ Clamp Type Inlet/Outlet, Includes Big Wheel Feed System & Controller Mounted on Wall, with S/S Control Panel, Includes Allen Bradley 7-Slot PLC, with Allen Bradley PanielView 550, with Diversey Flow/Temp. Transmitter, with Associated Valving and Piping

- DeLaval Cold Bowl S/S Separator, M/N 425, S/N 3700043, with Motor

- DeLaval Cold Bowl S/S Separator, M/N 425, S/N 3702890, with Motor

BEAUTIFUL RAW & PASTEURIZED S/S TANKS

- DCI 6,000 Gal. S/S Jacketed Horizontal Tank, S/N 94-D-49417-B, with (2) Quad Prop S/S Veritcal Agitators, with (2) Dual CIP Spray Balls, with Air Valve, with Painted Exterior

- DCI 6,000 Gal. S/S Jacketed Horizontal Tank, S/N 94-D-49417-A, with (2) Quad Prop S/S Veritcal Agitators, with (2) Dual CIP Spray Balls, with Air Valve, with Painted Exterior

- Mueller 6,000 Gal. S/S Jacketed Horizontal Tank, S/N 1833400, with Dual Prop S/S Vertical Agitation, with Dual CIP Spray Ball, with S/S Air Valve, MAX W.P. 170 PSI @ 100 F, 0 F @ 170 PSI, NAT’L BD Number: 24843

- DCI 5,000 Gal. S/S Jacketed Horizontal Tank, S/N 95-D-51257, with (3) CIP Spray Balls, with (2) Veritcal S/S Agitators, with 4-Props, with S/S Face, with S/S Air Valve

- Cherry-Burrel 3,000 Gal. Jacketed Horizontal Tank, with Dual S/S Spray Ball, with Quad Prop Veritcal S/S Agitation, with S/S Exterior

- Dari-Kool 3,000 Gal. S/S Horizontal Jacketed Tanks, with Vertical Agitation, CIP Spray Ball, and Air Valve, with S/S Exterior

- Sunset 1,000 Gal. S/S Jacketed Horizontal Tank, M/N MC-1025PX, S/N 21MC992, with (2) Vertical Dual Prop S/S Agitators, Overall Dims.: Aprox. 15’3″ L x 54″ W x 76″ H (NOTE: Formerly Used As Farm Tank)

FOGG & FEDERAL FILLERS WITH CHANGE PARTS

- Fogg 32-Valve Rotary Filler, S/N 715-1-4-99-LH, with (8) Head Rotary Capper, with Fogg Cap Feed System, S/N 621-71-4-99, Overall Filler Dims.: Aprox. 124″ L x 91″ W x 103″ H, with (2) Inlet Air Valves, with 10 hp Centrifugal Pump, with Baldor 3500 RPM Motor, Includes Manual (NOTE: Currently Set Up to Run Gallons)

- Federal 18-Valve Rotary Filler, with 5-Station Rotary Capper, with Stand Alone Capping Feed System, Mounted on S/S Frame, Overall Filler Dims.: Aprox. 79″ L x 51″ W x 91″ H, Overall Capping Feed System Dims.: Aprox. 33″ L x 32″ W x 105″ H, with S/S Panel with Magnetek GPD515 VFD

- Large Assortment of Fogg Change Parts and Spare Parts, Includes 2017 1/2 Gal. PL SQ Change Parts, S/S Change Parts Cart with Dedicated Racks, Infeed/Outfeed Change Parts, Aprox. (26) S/S Filling Rods, and Additional Parts As Photographed

- Large Assortment of Federal Filler Change Parts and Spare Parts, Includes Federal Capper Columns, Infeed/Outfeed Star Wheels, Filler Rubber Inserts, Used Bat, Spring, And Other Present Parts As Photographed

- Large Assortment of Product Conveyor and Newer Jug Conveyor

DEBAGGING & CASING EQUIPMENT

- AIS Debagging Table, with Table Top Single Filer, with S/S Discharge Conveyor, Aprox. 36″ W Table Top Conveyor, Includes S/S Discharge Conveyor, with 3″ W Chain

- AIS Debagging Table, with Aprox. 36″ W Table Top Conveyor, with Rebuilt Table Knife Cylinder, with Foot Control, and Square D Safety Switch

- Built Rite S/S Caser, M/N LT1313, S/N 112, 440 Volts, 3 Phase, with S/S Control Panel, Includes Allen Bradley SLC 500 PLC, Yaskawa GPD 315/V7 AC Drive & Yaskawa V1000 AC Drive, Includes Vertical Case Inverter

- Ex-Cell-O Corp. Case Stacker, M/N ST83-D, S/N 620, 1,000 Max. PSI, with SoCo. Case Conveyor Mounted Top Sealer, 8,334.4 Hours

- (2) Markem Imaje Ink Jet Coder, M/N 9020, with Digital Display, with Ink Head and Stand

- Case Washer and Case Conveyor System – Details Coming Soon!

ENGINE ROOM & PLANT SUPPORT

- AMMONIA REFRIGERATION

- Vilter 125 hp 6-Cylinder Reciprocating Ammonia Compressor, with Marathon 1780 RPM Motor, 460 Volts, 3 Phase

- Vilter 60 hp 6-Cylinder Reciprocating Ammonia Compressor, with Marble 1750 RPM Motor, 208/440 Volts, 3 Phase

- Vilter 50 hp 6-Cylinder Reciprocating Ammonia Compressor, with Marathon 1760 RPM Motor, 190/380 Volts, 1476 RPM

- Vilter 50 hp 6-Cylinder Reciprocating Ammonia Compressor, with 1770 RPM Motor

- Vilter 50 hp 6-Cylinder Reciprocating Ammonia Compressor, with Reliance 1750 RPM Motor, 440 Volts, 3 Phase

- Frick 20 hp Screw Ammonia Compressor, with 1175 RPM Motor, 460 Volts, 3 Phase

- Ammonia Recirculation System/Skid, with Associated Piping & Valving, with Horizontal Ammonia Holding Tank

- Boiler System – Check Back for Details!

ICE CREAM DEPARTMENT

FLAVOR TANKS

- 3-Compartment 150 Gal. S/S Jacketed Flavor Tank, with (3) Dayton 1/2 hp Vertical Agitation Motors, Compartment Internal Dims.: Aprox. 44″ L x 36″ W x 43″ D, Overall Dims.: Aprox. 120″ L x 5′ W x 74″ W

- 4-Compartment 500 Gal. S/S Jacketed Flavor Tank, with (4) Vertical Top Mounted Agitation Motors, with (4) Bottom Mounted S/S Air Valves, Overall Dims.: Aprox. 203″ L x 70″ W x 73″ W

- 1-Compartment 1,000 Gal. S/S Jacketed Square Flavor Tank, Aprox. 83″ L x 67″ W x 91″ H, with Top Mounted Agitation

ICE CREAM FILLER, FREEZERS & FRUIT FEEDING

- Crepaco S/S Fruit Feeder, S/N S-420 C67447, with (2) NEW Dayton Variable Speed Belts, Mounted on Casters, with Digital Read Out

- (2) S/S Double Barrel Ice Cream Freezers, with NEW Spare Belts

- S/S Dual Station Ice Cream Filler, with Dual Outlet & Tub Station, Aprox. 48″ L x 27″ W x 38″ H S/S Table

SUPPORT TANKS

- (2) Mueller 1,000 Gal. S/S Jacketed Horizontal Tank, with Top Mounted Agitation, Overall Dims.: Aprox. 102″ L x 73″ H, with Mueller Temperature Panel