JUICE BLEND ROOM (MAIN PLANT)

- Howard 6000 Gal. Dome Top, Cone Bottom S/S Tank, SN U1601B, with Wide Sweep Hyd. Agitator, Ammonia Jacketed, 116″ Dia.

- (5) 6,500 Gal. Dome Top S/S Mix Tank, with Dual Hydraulic Vertical Agitators, 9 ft. Dia.

- (6) TC PR 300 Positive Displacement Pumps

- Waukesha 60 Positive Displacement Pump

- (2) Small S/S Balance Tanks

- Waukesha Positive Displacement Pump

- (2) 3″ SS Floverter Station with Installed S/S Piping

- Ampco 30 hp High Shear Pump, Model SBIV530-252-28, SN CC-97860-1-1, 3520 RPM, 208-230/460V – 3Ph (See photo for data)

S/S TANK FARM (MAIN PLANT)

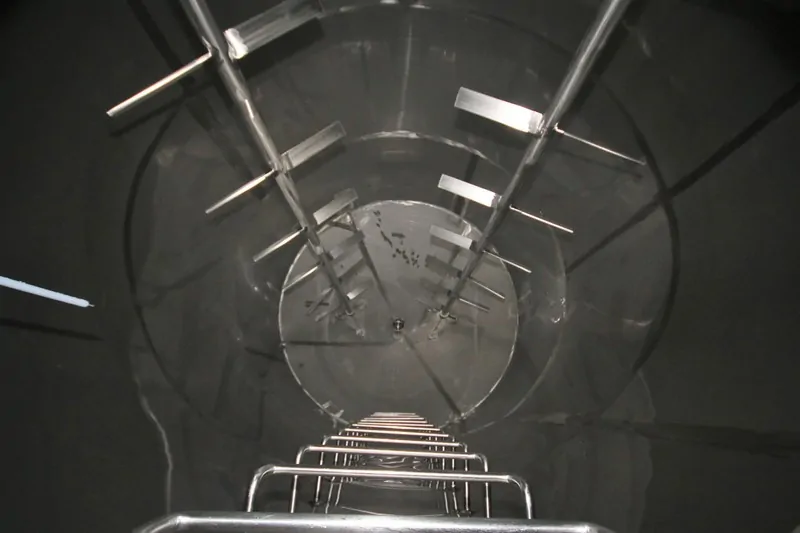

- (16) 150,000 Gal Vertical S/S Holding Tank, with Sloped Bottoms, 384″ Dia.

- (4) 50,000 Gal Vertical S/S Holding Tanks, Dia. 210″

- (1) 35,000 Gal. Vertical S/S Holding Tanks, Dia. 210″

- Aprox. (20) Tri Clover PR300 Positive Displacement Pumps with Hydraulic Drives Throughout Tank Farm Area

- Tank Cleaning Heads

- (2) Gamma Jet (Alfa Laval Type) Tank Washers, Gear Driven, with Manifold, (Cost $12k each new)

- Tank Farm Modular Cooler Building:

- Aprox. 40,000 sq. feet, 38 ft Ceiling Equipped with Removal Panels, Rubberized Roof with Associated Ammonia Evaporators

S/S TANK FARM (SECOND LOCATION)

- (3) 10,000 Gal. Vertical Cone Bottom Mix Tanks with Cleveland Elect. Drives, (2) 12 ft W (No. 1 & 2) x (1) 13 ft W (No. 3) x 12 ft H, All Mounted on Load Cells (Overall Height 210″)

- Waukesha 130 Positive Displacement Pump, SN 190147-96 with 3″ CT Head, 15 hp electric drive mounted on SS frame

- Cone Bottom, Single Wall, 169″ H x Aprox. 14 ft W (Tank 4)

- (3) Single Wall, Sloped Bottom Tanks, 160″ W x 168″ H (Tank 5,6 & 7)

- Bohn Blower 3 Fan Evaporator Freon

- Case Sealer Bottom Type

SMALLER S/S TANK FARM (SECOND LOCATION)

- (1) Aprox. 5,000 Gallon, 120″ W x 117″ H – Cone Bottom Tank with Agitator

- (1) Aprox. 2,000 Gallon, 72″ W x 108″ H Tank with Agitator

- 1977 C.E Howard 6,200 Gal. SS Tank Single Wall with Alcove, SN 14436A, 136″ H x aprox. 10 ft W

BARREL FILLING ROOM (MAIN PLANT)

- JVT Skid Mounted S/S Jacketed Typhoon Chopper, 52″ W x 69″ H, with Aprox. 600 Gallon Barrel Dumper & Waukesha PD Pump

- (2) Aprox. 800 Gallon Dome Top, Cone Bottom Vertical S/S Tanks, 60″W x 72″ H

- 55 Gal. S/S Barrel Filling System with Mag Trap, Conveyor System & Controls

- (2) S/S Diaphragm Pumps, (1) 3″ & 2″

- 3″ SS Filter

AMMONIA COMPRESSOR ROOM (MAIN PLANT)

- (2) M&M 100 hp Ammonia Screw Compressors, (see photos for data)

- Ammonia Accumulator & Receiver Skid

- Evapco Condenser 2 Fan, Model PMC190E, SN 9354555

- Compressor Control Cabinet

- Allen Centerline Bradley MCC

- Main Entrance Elect. Panel

- Vilter 4 Cylinder Ammonia Compressor, (Uninstalled)

- Air & Hydraulic System (Outside)

- IR Screw Compressor, Model SSR-UP6-25-125, SN PY1926U09175

- IR Refrigerated Air Dryer & Vertical Receicer

- Hydraulic System with 2016 125 hp New Pump with SVX 9000 VFD, with (4) additional Hydraulic pumps with Reservoir & Circulation System

- AB Centerline MCC

TANKER RECEIVING (MAIN PLANT)

- (2) 70 ft x 10 ft W Above Ground Truck Scales, (1) Later Model Mfg by Air – Weigh both with Read-Outs

- Outside Tanker Receiving & Load Out System

- (2) TC PR300 PDP with 4″ Flanged Heads & Hydraulic Drives

- Installed S/S Piping with Fittings Throughout Tanker Area

- Steel Truck Canopy Aprox. 40 ft W x 100 ft L 19 ft H with I Beam Construction

- 3 – Tank Skid Mounted S/S CIP System, Includes Aprox. 500 Gal Tanks, with Schmidt Plate Press, Related Valves, Ampco Centrifugal Pump, PLC Controls

- 2014 Designed (5) – S/S Tank Waste Water Pre Treatment System, with Agitation, Aeration, Sensors, Pumps & Controls, Note: (4) Tanks Added 2014

WASTE WATER TREATMENT (MAIN PLANT)

- 2014 Designed (5) – S/S Tank Waste Water Pre Treatment System, with Agitation, Aeration, Sensors, Pumps & Controls, Note: (4) Tanks Added 2014

LAB

- Maselli Brick Tester (11k new), (2 years old)

- Thermo Spectronic 200

- Hach Turbidimeter 2100N

- Other Lab Items – (See Photos)

- Other Major Additional Items to add!

MATERIAL HANDLING (MAIN PLANT)

- TCM LP Forklift 171″ Aprox 4,000 lb

- Drum Lift Attachment

- 6 Additional Forklifts

SPARE PARTS AND MAINTENANCE SHOP (MAIN PLANT)

- (2) Trailers Equipped with Complete Maintenance Shop including Tools, Machines and Spare Parts Inventory (Details to Follow)

OUTSIDE STORAGE (MAIN PLANT)

- International 1000 kva 3 phase Transformer, 4160V, (Uninstalled)

- Pallet Racking (Uninstalled)

- (3) Waukesha PDP, (2) with Electric Drives, (1) with Hydraulic Drive

- Material Handling & Spare Parts & Maintenance

OUTSIDE STORAGE (SECOND LOCATION)

- Gardner Denver 25hp Air Compressors with Horizontal Tank

- Curtis 25 hp Screw Air Compressor

- Honeywell’s 25 hp Air Compressor

- Vilter Compressor VMC 320 – 4 cylinder – on Skid (Uninstalled under tarp)

- Vertical S/S Tank with Vertical Agitator with Steel Exterior, 128″ W x 122″ H, (Uninstalled Rough Condition from Outside)

- Vertical SS Tank with Agitator, 70″ W x 10 ft H, Single Wall with Cone Bottom, (Uninstalled)

- Recold Condenser

- Vertical Hydraulic Baler