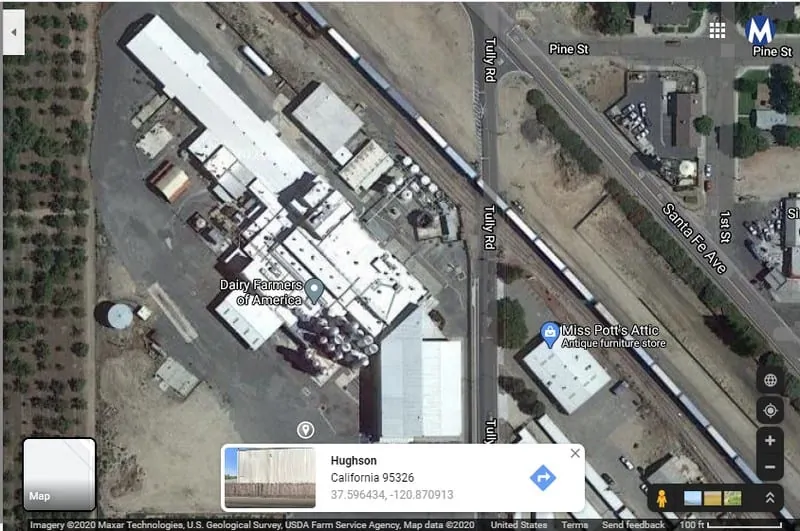

REAL ESTATE AND LAND

- 70,606 Sq Ft food processing plant on 14.59 acres. 83 miles from Sacramento, 93 miles from San Jose, and 102 miles from San Francisco.

- Address: 2331 Tully Rd, Hughson, CA 95326

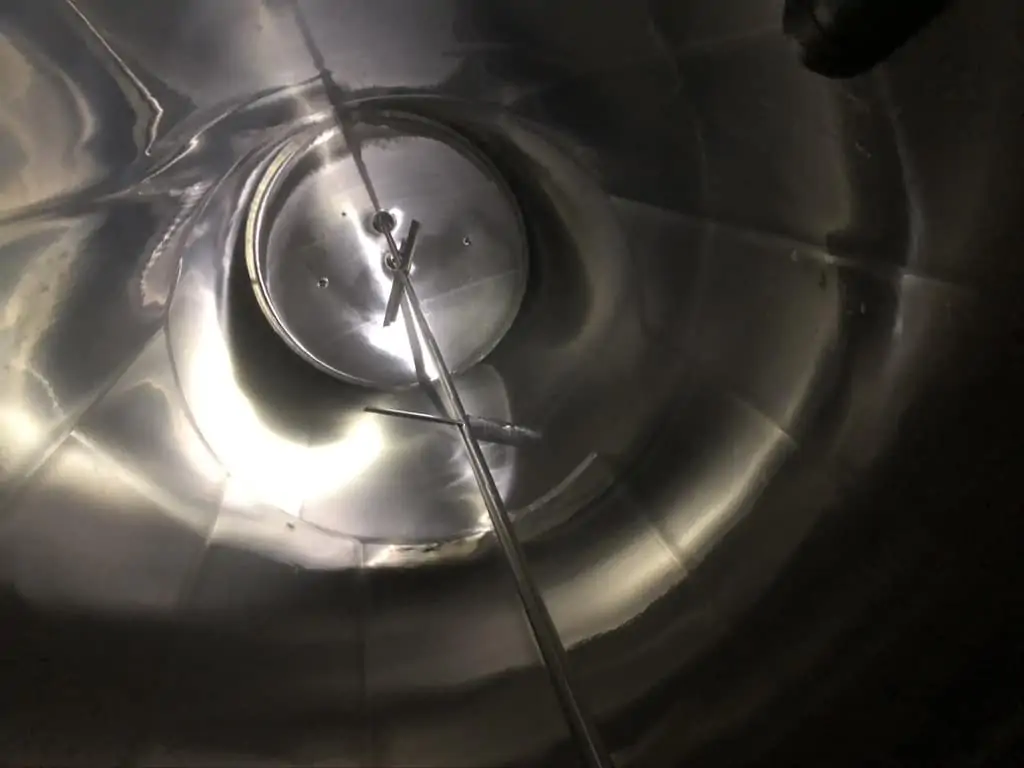

SILO INTAKE SILO ALCOVE AREA INCLUDES (10) S/S SILOS, (MOST GLYCOL JACKETED)

- 3 – Feldmeier 60,000 Gal, SN N-0006-09, with Horizontal Agitator

- 1 – Crepaco 25,000 Gal, S/N 2961, Air Agitated

- 4 – 1971 Walker 40,000 Gal, Air Agitated

- 5 – 1975 Walker 40,000 Gal, Air Agitated

- 6 – Crepaco 40,000 Gal, Air Agitated

- 9 – Mueller 40,000 Gal, Model SWV, SN 324951-1, with S/S Exterior

- 2013 Feldmeier 40,000 Gal, Horizontal Agitator

- 8 – Mueller 40,000 Gal, Horizontal Agitator

- “Other Items In Silo Alcove Room: (5) Fristam & Other Centrifugal Pump, 2-Comp. S/S COP Sink with Fittings, Solonoid & Other Control Panels, Installed S/S Piping, Valves & Fittings

- New Condensed Silo Alcove Room – (Built 2015), (Glycol Jacketed)

- Other Items in Condensed Silo Room Including: (2) Valve Cluster Racks with (43) & (45) Pentair 3″ Mix Proof Valves with (2) Micro Motion 3″” Flow Meters, (6) Fristam Centrifugal Pumps

- Main Processing Floor

- RO System Includes:

- (10) 8″ S/S Membrane Tubes 17 ft 8″ L on Rack, (2) 4″ S/S Membrane Tubes 16 ft 9″ L on Rack, (8) Fristam Pumps – (2) Models 4030, Most 25 hp, Filtration Eng. Control System, 08 Sprinkman 200 Gal S/S Tank with Platform, Related Valves & Piping

- 2007 Westfalia CIP Separator, Model MSD-300-01-777, SN 1715933, with Related Valves & PLC Controls (Separator #1)

- HTST System (Larger System) Includes:

- 07 Tetra Pak S/S Plate Press, Model Tetra Plex 08-KSH, SN 30110-71685, with (1) Divider, Includes WCB 2.5″ Flow Diversion Valve, 2.5″ Nested Holding Tube, Balance Tank, Related Valves, Piping & Controls (#5)

- HTST System (Smaller) Includes:

- 07 Tetra Pak S/S Plate Press, Model Tetra Plex C6-SH, SN 30110-71683, with (3) Dividers, Includes WCB 1.5″ Flow Diversion Valve, 1.5″ Nested Holding Tube, Balance Tank, Related Valves, Piping & Controls, Waukesha Timing Pump, Centrifugal Pump (#4)

- Cream Press Includes:

- 07 Tetra Pak S/S Plate Press, Model Tetra Plex C6-SH, SN 30110-71684, with Related Valves

- Cream Chilling Press (Behind CIPs) Includes: 08 APV Paraflow S/S Plate Press

- HTST System with Homogenizer Includes:

- AGC S/S Plate Press, Model Pro 31M, SN C11307, with (2) Dividers, Includes Tri Clover 2.5″” Flow Diversion Valve, 2.5″” Nested Holding Tube, Balance Tank, Related Valves, Piping & Controls, (3) Fristam Centrifugal Pumps; Gaulin Homogenizer, Model 2000-MC18-2.5TPS, SN 12777389 with HVA (#3)

- Polished Water RO System Includes:

- (4) 8″” S/S Tubes – 17 ft 9″” L, with Fristam 30 hp Centrifugal Pump, 48″ H x 42″ W Skid Mounted S/S Tank, (2) Fristam Centrifugal Pumps, Related WCB Air Valves, Flow Meters Grundfos Pump & Controls

- (2) Process CIP Systems Includes:

- Raw / Outside System –

- Sani-Matic 3-Tank Skid Mounted S/S CIP System, with Aprox. 700 Gal (78″” H x 53″” W) S/S Tanks, S/S Shell & Tube Heat Exchanger, Centrifugal Pump, Related WCB Air Valves & Piping, Allen Bradley PLC Controls, Operators Platform

- Pasteurize System (Inside) –

- Sani-Matic 3-Tank Skid Mounted S/S CIP System, with Aprox. 300 Gal. (58″” H x 38″” W) S/S Tanks, Enerquip S/S Shell & Tube Heat Exchanger, Fristam Centrifugal Pump, Related WCB Air Valves & Piping, Allen Bradley PLC Controls, Operators Platform

- Condensed & Cream Silo Alcove Area

- (5) S/S Silos (Most Jacketed with Agitators) Includes:

- APV Crepaco S/S Silo, S/N C2808, with Horizontal Agitator, (Cond. Tank 5A)

- Mueller S/S Silo, SN D-4338, (Cream Tank 4A)

- Cherry Burrel S/S Silo, Model SVW, SN 120-73-338, (Cream Tank 1A)

- Cherry Burrel S/S Silo, (Cream Tank 2A)

- Mueller S/S Silo, SN D-4339, (Cream Tank 3A) (Note: Possibly 6,000 Gal Silos)

- Condensed & Cream Pumps Including:

- SPX 3″ Positive Displacement Pump (Large); Waukesha 3″ Positive Displacement Pump; Fristam Centrifugal Pump

- Other Items in Condensed & Cream Silo Alcove Area:

- 06 AGC S/S Plate Press, Model 300-S, SN 06315, (46″ H x 23″W)

- Jet Spray S/S COP Tank, 15 ft L x 25″ W x 20″ D, with Centrifugal Pump

- (2) Recon Powder Tanks Includes:

- (2) Walker 7,000 Gal. Horizontal S/S Tanks, Model HHT, SN SPG-53754-1 & 2, with Vertical Agitator, S/S Fronts, 10 ft 5″ W, (Glycol Jacketed) (Recently Refurbished)

- Condensed Skid – Dryer Feed System Includes:

- 2016 Skid Mounted Unit with AGC S/S Plate Press, Model PRO2S, SN 2016295, (2) 36″ H x 34″ W S/S Tanks, (3) Fristam 15 hp & 3 hp Centrifugal Pumps, CFR S/S Shell & Tube Heat Exchanger, Related Pentair S/S Air Valves, Piping & Touch Pad Controls

- HTST System – Includes:

- 2017 AGC S/S Plate Press, Model PRO31H, SN 201719S, with Self Contained Hydraulic Close, (2) Dividers, Balance Tank, Enerquip Shell & Tube Heat Exchanger, (3) Fristam Centrifugal Pumps, Related Valves & Controls

- HTST System Includes: APV S/S Plate Press, Model SR310, SN 22353, with (1) Divider, SPX 2″ Flow Diversion Valve, 3″ Round Holding Tube, Related Valves & Piping & Controls, Waukesha Timing Pump & Fristam Centrifugal Pump

- Westfalia CIP Separator, Model MSD-300-01-777, SN 1713656, with Related Valves & PLC Controls (#2)

- Other Items Throughout Process Room Includes:

- Central Valve Cluster Rack, (Serving HTST Systems); (16) SPX 3″ Mix Proof Air Valves, (3) Micro Motion 3″” Flow Meters, Additional Pumps, Valves, Fittings, 1,000’s of Feet on Installed S/S Piping with Floverter Valves & Related

HALLWAY / THROUGH WAY AREA

- Motor Control Centers – (3) Allen Bradley 20 to 40 Bucket MCC with Allen Bradley VFD’s

- Tri Blender – (Recon Room) – Tri Clover Tri Blender, Model FX329MD-B40, 20 hp

POWDER DRYER EQUIPMENT

- Approx. 40 ft H x 10 ft W S/S Tower Dryer with Natural Gas Burner, Associated Duct Work, 4 – Level Operators Platform, Related Valves, Piping & Controls

- (2) Additional Approx. 10 ft W S/S Powder Cyclones

- 2015 GEA Niro Soavi High Pressure Pump / Homogenizer, Type NS3090P, SN 11662, 3 – Piston Design

- Approx. 200 Gal. (32″ H x 44″ W) Dome Top S/S Tank with Centrifugal Pump

- Dryer Powder Baghouse – System Built 2017 ($5 Mil. Project) Includes:

- S/S Baghouse Chamber with Associated Duct Work, Fan, Valves & Controls, (Note: Chamber Damaged from Fire)

- Humidification System Includes Air Handler & Related

- Powder Filling Line Including:

- S/S Rotary Powder Filler with Fairbanks Scale; 2008 Doboy / Bosch Bag Sealer, Model HDPT-40, SN 08-28074; Safeline Powerphase Plus S/S Metal Detector with 24″” W x 10″” H Opening, Mounted on Conveyor; Related Conveyor System; Diagraph IJ3000 Ink Jet Coder with (4) Heads; Additional Items In Room Includes Label Printer, Vacuum Lift System, (2) Canaster Vacuums

MILK EVAPORATOR ROOM

- Mojonnier S/S Horizontal MVR Evaporator System, with Collandrias & Difuser, MVR by Louis Allis 600 hp / 1700 rpm, Associated Duct Work, Pumps, Valves, Shell & Tube Heat Exchanger, Piping & Controls

- AGC S/S Plate Press with (2) Dividers, (Larger System), with S/S Balance Tank & Holding Tube

- S/S Vertical Tank with Pump

COOLER / WAREHOUSE AREA

- Forklifts Including:

- (2) Hyster Stand Up Electric Forklifts with Chargers; Raymond Stand Up Electric Forklifts with Charger

- Cooler Racking System with Aprox. (576) Pallet Space Includes: Drive In Style Pallet Racking System, 4 High x 4 Deep x 2 Row, 36 – Total Sections, Bolt Constructed; (2) Sect. Standard Pallet Racking

- Modular Cooler Includes: Late Model Standex 16 ft L x 7 ft W x 8 ft H Modular Cooler with Freon Refrigeration System

- Surplus Equipment in Cooler Includes:

- Skid Mounted Tank System with Feldmeier 42″W x 31″ D S/S Tank, SN E61008, with Agitator, (316L), Fristam Centrifugal Pump & Controls with AJ-300 Chart Recorder

- Assorted Packaging Materials in Cooler Includes: Assorted Pallets of Packaging Materials Including Shrink Wrap & Tape

- Cooler Freon Refrigerant System Includes: (8) 2 – Fan Evaporator / Blowers with (3) Recip. Compressors

DRY STORAGE WAREHOUSE AREA

- Flex Kleen Dust Collector, Model 84-BVBS-3611, SN N-52-18663

- Other Items in Warehouse Area Include: Tennant 5700 Walk Behind Floor Scrubber; (2) Hyster Sit Down Electric Forklifts with Chargers; Hyster Sit Down LP Forklift with Charger; (5) Sect. of Standard Type Pallet Racking; Hydraulic Pallet Jack

AMMONIA REFRIGERATION ROOM

- Ammonia Refrigeration Equipment Includes:

- 2017 Frick Screw Ammonia Compressor, Head Model S6C1918, SN 11531M43272443, 335/385 HP, 715/3574 RPM

- (2) FES Ammonia Screw Compressors, Models 180-ME & 13L, SN 2053312 & 13L121LS-3,

- Additional Spare Screw Compressor in Storage;

- (4) BAC Evaporative Condensers, Models C2664MMPH, VXC-N230RP, 15350R & F1343-NR, SN 89201806, 86-1144M, 97219181, 89200116

- Ammonia Circ. System

- Glycol System (Ammonia Chilled) Includes:

- FES Painted S/S Plate Press with 6 ft x 8 ft x 12 ft S/S Holding Tank, Circulation System with (3) Centrifugal Pumps & Receiver

- CIP System (In Room) – Skid Mounted Single Tank CIP System with Mounted Shell & Tube Heat Exchanger, Pump, Valves & Related Piping

PLANT AIR SYSTEMS

- (3) Quincy 75 hp Screw Air Compressors, Model QGV-75;

- 2014 Kaeser Refrigerated Air Dryer, Model ASD25;

- Air Circulation System

BOILER ROOM

- (2) Horizontal Boiler Systems Including:

- (1) Cleaver Brooks & (1) Johnson Cat. No. 528-AHG with Updated Burner System & Circulation System; Siemens Water Softening System; Tomar Small 7- Tube Water RO System

PLANT CONTROL ROOM – (Near Plant Support Equipment)

- Motor Control Room Includes: (1) Allen Bradley MCC; Square D Main Switch & MCC Panel

SPARE PARTS BUILDING

- Large Assortment of Spare Parts Throughout Room Includes:

- Spare Parts for Most Major Machinery Including Homogenizer, Separator, HTST Systems, Tank Parts, Dryer & Evaporator, Ammonia Parts, Air Compressor Parts, Sanitary Valves Parts, Sanitary Pump Parts for Centrifugal & Positive Displacement, Electrical Including Allen Bradley VFD’s & PLC Components, Starters, Switches, Anderson Controls, Control Panels & Related, Large Assortment of Spare Motors & Drives, Pumps, Air Parts, Hydraulic Parts, Plumbing Parts & Related, Chemical Pump Parts, Assorted Gauges, Drive Parts Including Bearings & Seals, Sprockets & Pullies, Aprox. (10) Lista Parts Storage Cabinets, Bolt Bins with Hardware, Assorted Steel Shelving

GENERAL PLANT

- Assortment on General Plant Items Including: (2) Smart Step Boot Washers; Eyewash Stations, S/S Sinks, Dollies, Carts, Chemical Handling Equipment, Fireproof Cabinets, Ladders, Cage Racks, Rubbermaid Garbage Cans & More

OTHER ADDITIONAL ITEMS

- (2) Cargo Shipping Containers for Storage

MAINTENANCE SHOP

- Jet Vertical Milling Machine

- Dayton 20″” Drill Press, Double End Grinder

- Press Brake, Hydrauic Press

- (2) Steel Welding Tables

- Lincoln Portable Fume Hood

- Lincoln Mig 15 Welder

- Jet Saw

- Ridgid Pipe Threader

- Chopsaw,

- Large Assortment of Handtools in Boiler Room Cage Area;

- Knaack Tool Box & Tool Box in Storage Warehouse

SURPLUS EQUIPMENT OUTSIDE

- Assorted Equipment Including Air Valve Cluster & Tote Filler

LAB

- Assorted Lab Equipment

- Late Model Lab Furniture

MILK TANKER RECEIVING BAY

- (3) Receiving & Load – Out Platforms; (6) Centrifugal Pumps with Filters, Valves & Piping

- 2017 Atlantium HOD In-Line S/S UV System, Model RZ163-12-HP, SN F2NF01171714, 480V 3 Phase

- (2) Aprox. 1,500 Gal. (10 ft H x 5 ft W) Cone Bottom S/S Chemical Tanks

- 2 – Tank CIP Systems with Heat Exchangers, Pumps & Valves

- Poly Chemical Tank with Containment

- In- Ground Truck Scale with Read – Out

- Aprox. 500 Gal. Dome Top S/S Tank with Pump, (Located Near Condensers)

- Large Bulk S/S Chemical Tank with Containment

- Additional Small BAC Condenser – (In Front of Building)

- Fire House Equipment

PLANT WASTE TREATMENT SYSTEM

- Assortment of Various Tanks Throughout Area, Some S/S Silos

- DAF System

- 2007 Filtration Engineering Waste Treatment S/S RO System, Model 11800-RO-01, SN 07-386

- Control System

OFFICE

- Assortment of Furniture Throughout Main Office Including Desks, Chairs, File Cabinets, Conference Table, Assorted Office Machines